|

|

| Notable Features | |

|

|

Semi precast slab and beams |

|

|

Precast staircases |

|

|

Composite columns with steel formwork |

|

|

Aluminum and steel formwork |

|

|

Hardiwall partitions |

|

|

Use of jump lift |

|

|

Reusable safety system |

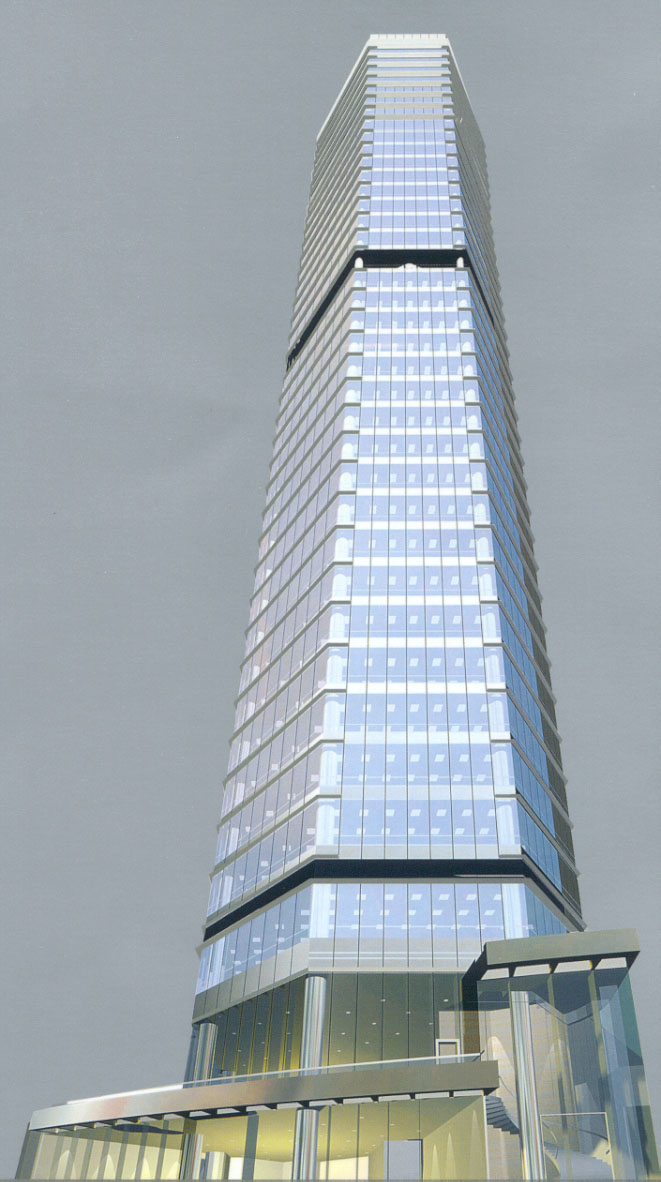

| Basic Information | |

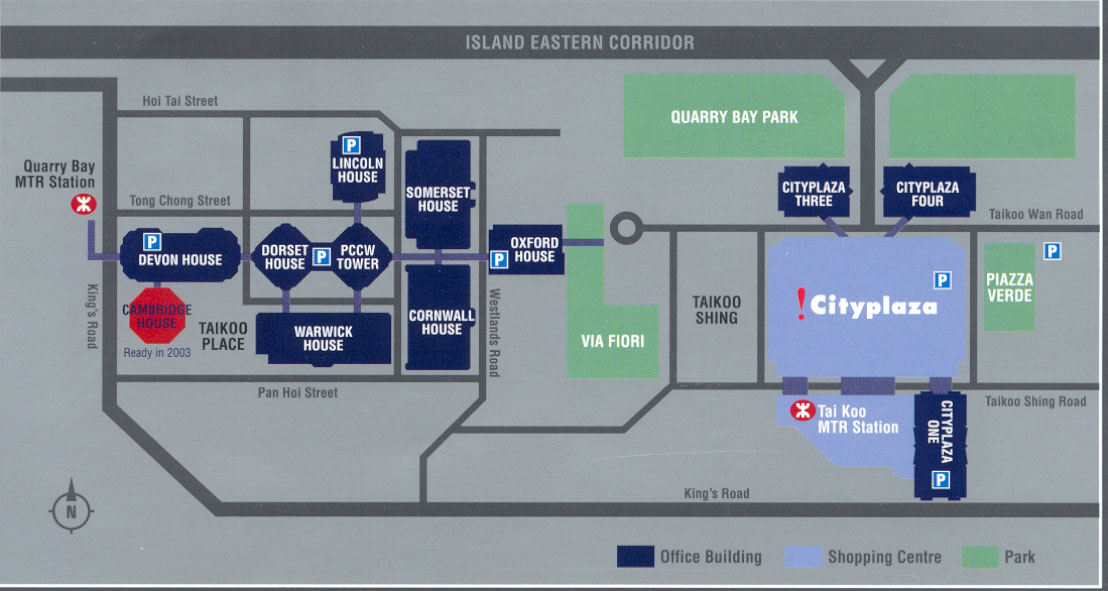

| Location: | |

|

Taikoo Place, 979

King's Road, Quarry Bay, Hong Kong |

|

| Building Type : | |

| Office | |

| Contract Period: | |

|

29/10/2001 - 21/04/2003 (540 days) |

|

| Contract Sum : | |

| Approximately HK$420 million | |

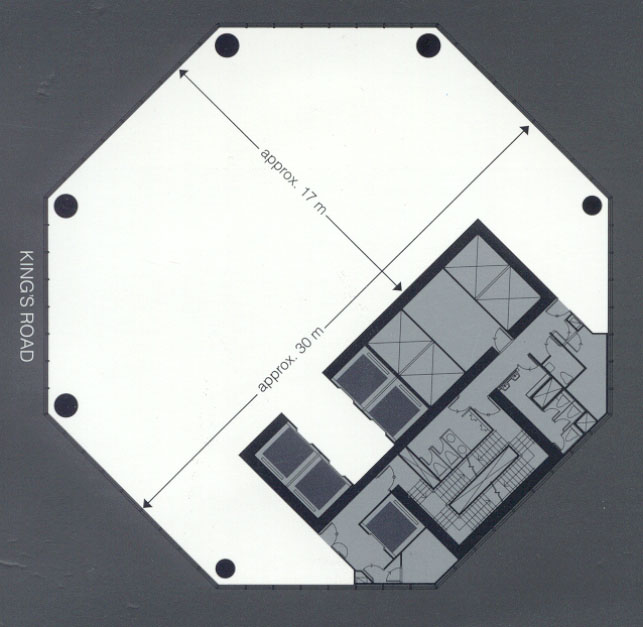

| Site Area : | |

| 6,700 sqft | |

| Gross Floor Area : | |

| Total construction floor area:31,140 m2 | |

| Typical Floor Area : | |

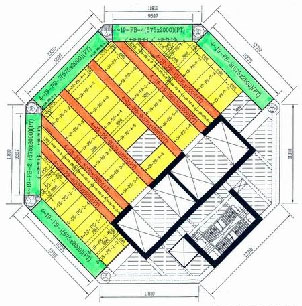

| 795 m2 | |

| Client : | |

| Taikoo Place Holdings Ltd. | |

| Client's Project Manager : | |

| Swire Properties Ltd. | |

| Architect : | |

| Wong & Ouyang (HK) Ltd. | |

| Structural Engineer : | |

| Maunsell Structural Consultants Ltd. | |

| E&M Consultant : | |

| Meinhardt (M&E) Ltd. | |

| Quantity Surveyor : | |

| Levett & Bailey Chartered Quantity Surveyors Ltd. | |

| Main Contractor : | |

| Hsin Chong Construction (Asia) Ltd. | |

|

|

|

| . | |

| Overview | |

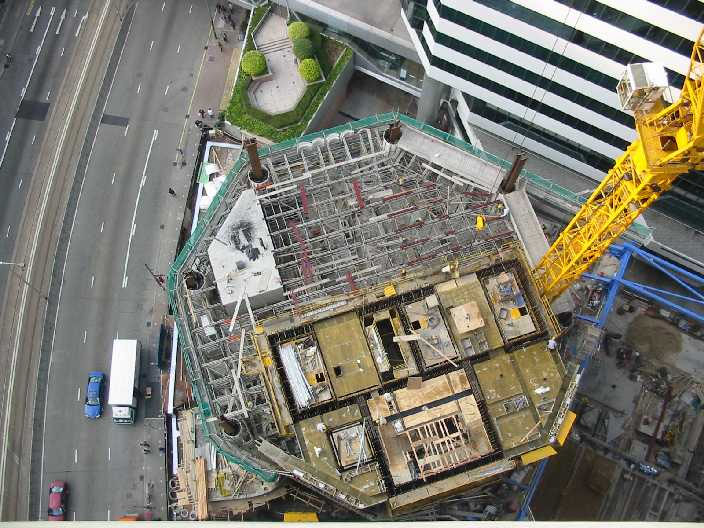

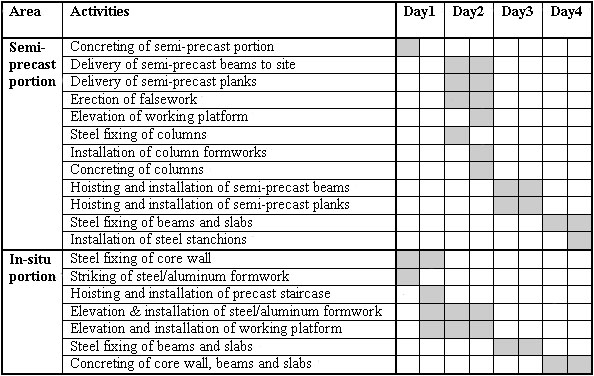

| This 36-storey grade A office building includes a 2-storey podium and a 1-storey M/E floor. The total construction floor area is 31,140m2, and each typical floor area is 795m2. Typical floors construction (4 days cycle) is split into two portions: semi-precast portion and in-situ portion. The in-situ portion is two floors ahead the precast portion. 95% BS Components off-site prefabricated. | |

| Precast portion: | |

|

|

Precast floor from 3/F to 21/F: 11 beams, 44 planks, and 3 stair modules per floor. |

|

|

Precast floor from 22/F to 36/F: 12 beams, 48 planks, and 3 stair modules per floor. |

|

|

| In this project, the choice for precast construction method is due to its lower cost and shorter construction period. Although the technology used is more expensive than traditional methods, the total cost is lower because of the shorter construction period. The in situ methods would have extended the construction for 2 months. | |

|

|

|

|

. |

|

|

Typical Floors Construction (4 days cycle) |

|

|

|

|

|

|

| Semi-precast Planks | |

| Semi-precast planks are delivered on site on Day 2, and hoisted and installed on Day 3. The plank dimensions are: max. Span 2.4 x 4.9 m2, and the max. Weight: 3.1 tons | |

|

|

|

|

|

|

|

|

|

|

| Semi-precast Beams |

|

Semi-precast beams are delivered on site on Day 2, and hoisted and installed on Day 3. The beam dimensions are: max Span 16 m, 575 mm depth, and max. Weight 10 tons. |

|

|

|

|

| Precast Staircases |

| Precast staircases are hoisted and installed on Day 1. The staircase dimensions are: max span: 6.9 m, and max. Weight 10.8 tons. |

|

|

|

|

|

| Columns |

| Steel fixing of columns, installation of steel column formworks and concreting (22m3) are done on Day 2. |

|

|

|

| Aluminum and Steel Formworks |

|

| Aluminum and steel formworks are used for the in-situ portion. Refer to the typical floors construction (4 days cycle) table for details. |

|

|

|

|

| Hardiwall |

|

Hardiwall system is used for internal partition. |

|

|

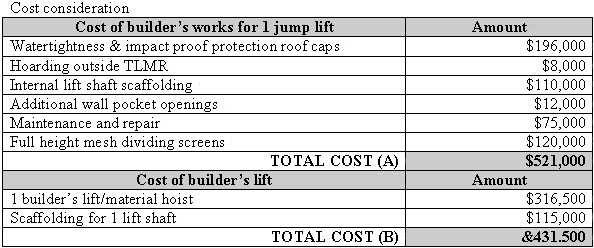

| Jump Lift |

|

Definition:

|

| Advantages: |

|

| Characteristics |

|

|

|

|

|

|

| Reusable Safety Systems |

|

All the safety

systems are reusable and easy to assemble: |

|

|

|

| Contact of Contractor |

|

Hsin Chong Construction Co.

Ltd. |

|

|