| Notable Features |

| |

|

Construction waste

reduction/recycling program |

|

Reduced

construction waste due

to use of factory manufactured precast concrete elements |

|

Application of

large panel steel formwork |

|

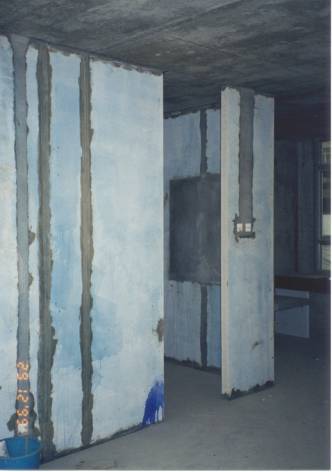

Use of drywall for

the internal partitions |

|

Use of

semi-precast slab |

|

Use of precast facade |

|

Use of precast

staircase |

|

Use of precast

cooking bench |

|

Use of

prefabricated door sets |

|

Use of spray plastering |

|

Use of gondola to

apply external finishes |

|

Use of steel

fabric reinforcement |

|

On-site sorting of

waste |

|

Reuse of steel formwork panels |

|

Reuse of surplus

steel bars |

|

Reuse of steel

hoarding |

| Basic

Information |

| |

|

Location: Cheung Sha Wan

West |

|

Building Type: Residential |

|

Contract Period: 2

years |

|

Scheduled Completion: Nov

2000 |

|

Client: The Hong

Kong Housing Authority |

|

Architect: Ho

& Partners Architects, Engineers & Development Consultants

Ltd. |

|

Structural Engineer:

Mitchell, McFarlane, Brentnell & Partners International Ltd. |

|

E&M

Consultant: Twin Way Consulting Engineers Ltd. |

|

Quantity Surveyor: C.

S. Toh & Sons & Associates |

|

Main Contractor: Yau

Lee Construction Co., Ltd. |

|

Contract Sum: HK$

750 million |

| Overview |

| |

| The

Cheung Sha Wan West Phase-II was a residential building project and

the following major items were executed under this contract: |

| |

|

1 no. 41 storey Harmony

1 (Option10), approximately 48 x 53 m overall on plan and

approximately 113 m high from ground floor to main roof level.

The long wing of each block is linked to its short wing with a

90o angle link core approximately 17 x 17 m overall on plan. The

block contains 79 no. Type 1P, 240 no. Type 1B, 320 no. Type 2B,

80 no. Type 3B rental domestic units in 40 domestic upper

floors. |

|

2 no. 41 storey Harmony 1

(Option 10) Blocks in Handed Version, each block approximately

48 x 53 m overall on plan and approximately 113 m high from

ground floor to main roof level. The long wing of each block is

linked to its short wings with a 90o angle link core

approximately 17 x 17 m overall on plan. The blocks contain 158

no. Type 1P, 480 no. Type 1B, 640 no. Type 2B, 160 no. Type 3B

rental domestic units in 40 domestic upper floors. |

|

1 no. 21 storey new

Harmony Annex 3 (Option 1), approximately 11 x 22 m overall on

plan and approximately 59m high ground floor to main roof level.

The block contains 140 no. Type 1P rental domestic units in 20

domestic upper floors. |

|

2 no. 21 storey new

Harmony Annex 4, approximately 21 x 17 m overall on plan and

approximately 59 m high ground floor to main roof level. The

blocks contain 320 no. Type 1P rental domestic units in 20

domestic upper floors. |

|

All associated drainage

and external works, including lorry parking areas, roads

emergency and service access, play areas, ball courts, covered

walkways, refuse collection point, junk collection point,

pavilion and landscape planters. |

|

| |

|

| |

|

| |

Plastering and Finishing

|

| |

|

|

|

| Since

the precast wall and floor slabs, as well as the factory

made internal walls provided very smooth and accurate

surfaces, thick plaster was not necessary. Plaster

dropping on floor during the finishing process,

sometimes accumulate to a thickness of 30mm over the

whole floor area, can hardly be avoided in traditional

cement sand plaster. |

|

However, with spray plastering the

same was not happened in this project. It also has the

advantage of higher productivity and lower demand of

labour.

|

|

| |

|

| |

|

| |

|

| |

Gondola

was used to apply external finishes. This saved the waste of

bamboo scaffolding. |

| |

|

| |

|

| |

Waste Management |

| |

|

| |

|

On-site

sorting of waste |

| |

|

| |

On-site

sorting was partially performed. Distributed Separation was adopted. The following materials

were sorted

out: |

| |

|

| |

|

|

Surplus

reinforcement – transported to the ground level by hoist

or tower crane |

|

|

Packaging material

– transported by hoist |

|

|

Rubble + foam +

plastic conduit – transported by refuse chute |

|

| |

|

| |

It

had been considered that the rubble/aggregate could be as

hardcore (size<200mm) for backfilling or sub-base for road.

However, there was no storage space for the rubble/recycled

aggregate. |

| |

|

| |

|

Material

Control |

| |

|

| |

|

|

The sub-contractors

were required to supply labourers as well as materials

such that they would reduce wastage of raw materials as

much as they could. |

|

|

Where the main

contractor supplied raw materials, sample floor/flat was

used to estimate the materials required, thus ensuring the

control of materials. |

|

| |

|

| |

|

Use

of recycled materials |

| |

|

| |

|

|

The

steel formwork had been used for another site already. It

would be reused or scrapped and transported to China for

resale depending on the condition of the material. |

|

| |

|

| |

|

Reusable

materials

|

| |

|

| |

|

|

surplus steel bars

were stored for reuse |

|

|

steel hoarding |

|

|

steel formwork |

|

|

steel protective

canopy of standard size at 1/F – it was first used for

this contract |

|

| |

|

| |

|

Steel

fabric reinforcement was used to reduce the waste

|

| |

|

|

|

|

![]() |

|

| Wall System |

| |

| Large panel

formwork was used to construct load-bearing walls of standard

domestic floors. Since all the wall formwork less than 7.5m

long was required to be cast in one piece, it minimised the number of

joints between formwork panels; therefore, less chance of

grout leakage or uneven surface finishes at joint which are

usually a norm for traditional timber formwork. For durability

and ease of maintenance of steel formwork, one set of formwork

can repetitively be used throughout the block. For instance,

one set of wallform was cyclically employed for the

construction of Harmony 1 housing block with four wings. At

the beginning, an 8-day floor cycle was adopted. As they had

got used to the technology, a 6-day floor cycle was

adopted. |

|

|

|

|

|

|

| It was

anticipated that the cost of steel formwork would be more or

less the same when compared with timber formwork for this

project. The

cost of steel formwork was even cheaper when the cost of

carpenter was increased to HK$3,000 per manday in the past.

|

|

| |

|

|

| Dry Wall |

| |

| The

internal partitions were built of factory made lightweight concrete

panels. Joints were minimized by the use of large size

floor-to-ceiling panels. Cutting was not necessary because the size

of the panels was tailored to suit the building, thus the amount of

waste that would be produced during construction was further

minimized. The time required was also less than the traditional brick

or block construction. |

|

|

|

|

| |

| The

factory made panel gives very smooth and accurate surface finish.

However, it might not be acceptable because of its lower strength in

supporting point load and resistance to impact. |

| |

|

|

| Slab

System |

| |

|

Semi-precast slab was adopted to

be the slab of each floor. 75mm thick precast slab was installed

first at the floor level which served as the formwork for the 95mm

thick in-situ concrete layer, thus forming a 170mm thick concrete

floor. This saved the time in erecting and striking the timber

formwork as well as forming a smooth ceiling finishes for the floor

below.

The cost of the semi-precast

slab is now competitive to the cost of timber formwork. However, the

precast slab must be handled and transported with care to prevent

cracking of the slab.

|

| |

|

|

| Precast

Facade |

| |

| The

precast facade was manufactured in China and transported to the site

for fixing. It was stored on the ground level and was hanged to the

required floor by tower crane. The precast facade with projecting

angle supports at both ends was placed in position on top of the

structural wall. Inclined bracing fixed onto floor slab was installed

to control the vertical alignment of the facade. Construction for

wall followed. Then precast slab panels were installed with

scaffolding supports. The top edge of the precast facade was right at

the top level of the floor slab, such that the precast facade formed

the stop end for the floor slab. |

| |

|

|

| |

| It

is cost effective to use precast facade in mass production. |

|

|

| Precast

Staircase |

| |

| The

precast staircase was constructed in 8 risers. According to the

building layout, the staircase was enclosed by structural walls on

two sides. The mid-landing was casted as in-situ with wall supports

on both ends. Due to the smooth surface quality, no applied finishes would

be necessary. A metal nosing strip was the only thing that was

required to finish the stair. Naturally, construction waste was not

arised. |

| |

|

|

| |

|

|

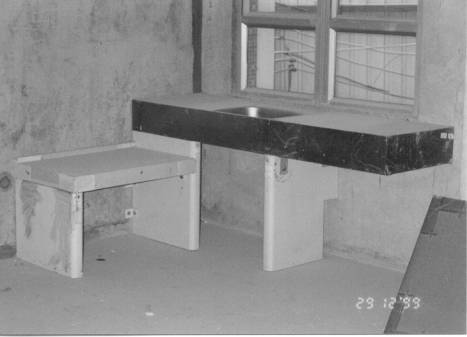

| Precast

Cooking Bench |

| |

| Cooking

benches were also prefabricated elements. Bench top was cladded with

1 piece 0.8mm satin finish stainless steel sheet. The bench itself

was of lightweight concrete and supported by 60mm concrete support,

smooth finish and epoxy painted. |

| |

|

|

| |

| The

stainless steel sink was cast in lightweight concrete bed, 75mm

thick, to afford strength to stand chopping and cutting. Earthing

lugs were designed and built for both sink and bench. |

| |

|

|

| Prefabricated

Doorsets |

| |

| Prefabricated

door frames and doors were used in this project. These doorsets saved temporary timber support for door frame, thus reducing waste. |

| |

|

|

| Contact

of Contractor

|

| |

| Yau

Lee Construction Co., Ltd. |

| 10/F.,

Tower I, Enterprise Square, 9 Sheung Yuet Road, Kowloon Bay, Kowloon,

Hong Kong |

| Tel:

(852) 2753 4388

|

| Fax:

(852) 2753 4300

|

| E-mail: info@yaulee.com

|

|

|

|