|

|

| Notable Features | |

| IFCII | |

|

|

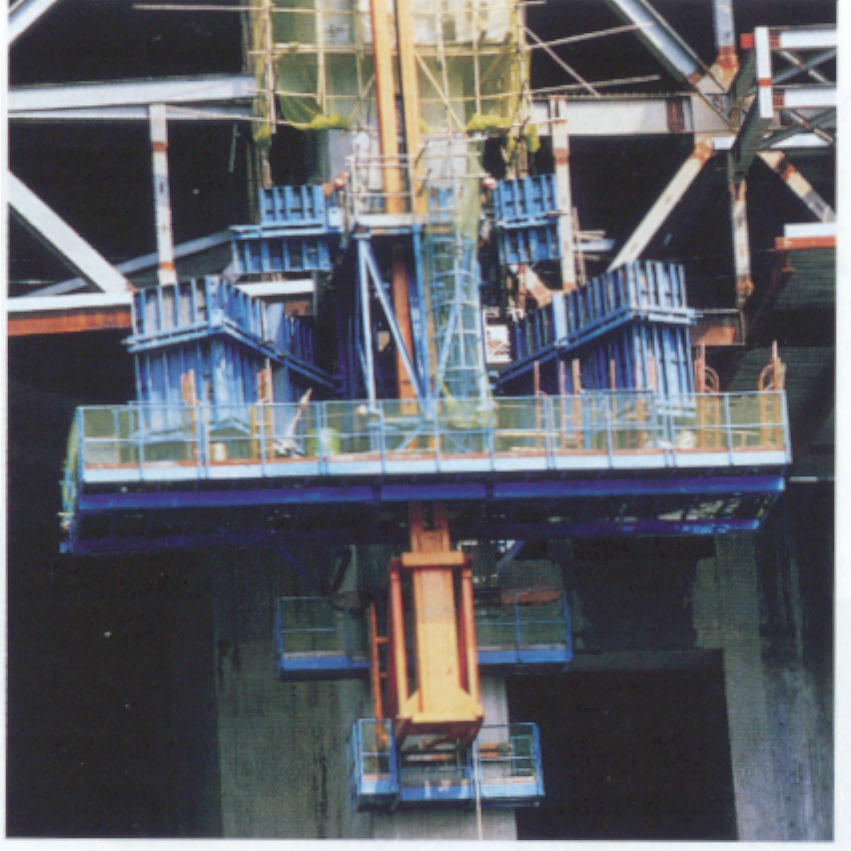

Steel structure with concrete core (hydraulic climb from system) |

|

|

Large composite mega-columns |

|

|

Steel permanent formwork for slabs |

|

|

Prefabricated staircases (steel and concrete) |

|

|

Hardiwall |

|

|

Raised access floor system |

|

|

|

|

|

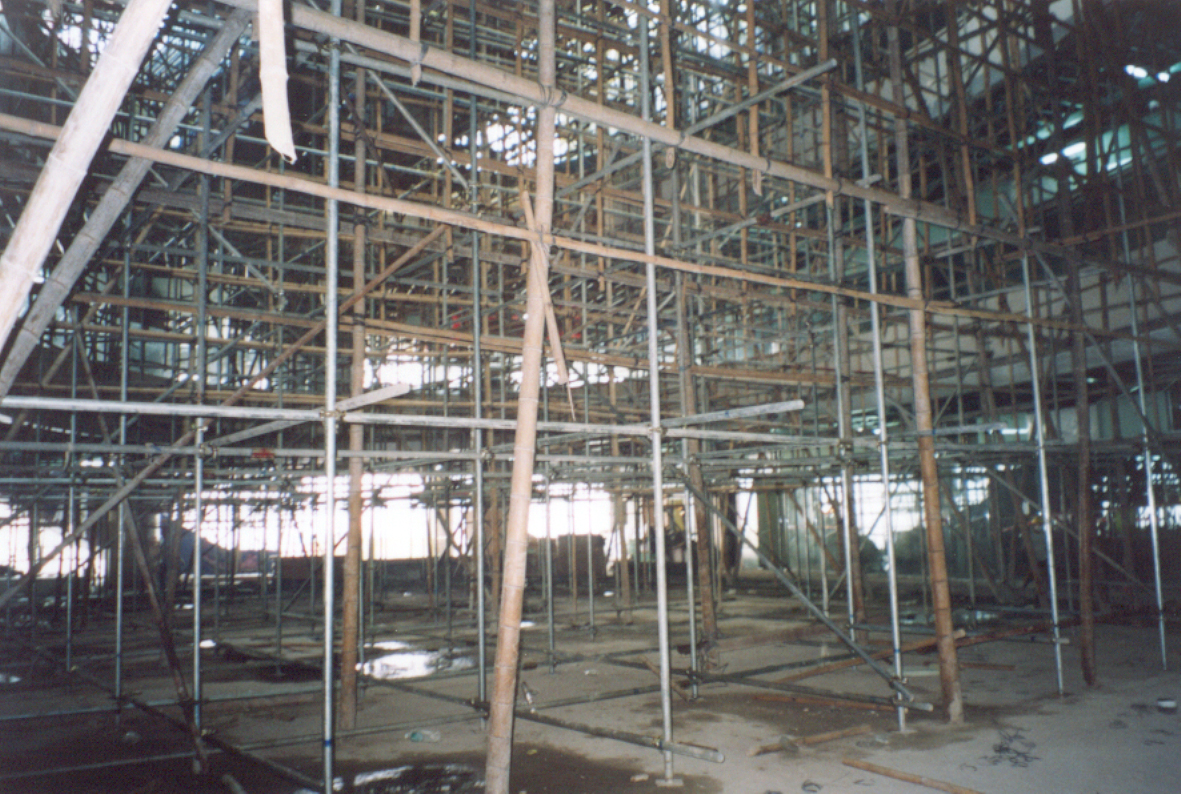

Metal and bamboo scaffoldings (inside works) |

|

|

|

|

Metal scaffolding (inside works) |

|

|

Prefabricated curtain wall |

|

|

On-site concrete batching plant |

|

|

Diaphragm wall cofferdam |

|

|

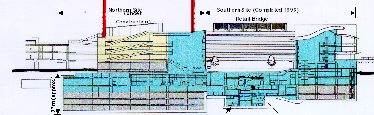

Top down construction technique (for 6 level basement) |

|

|

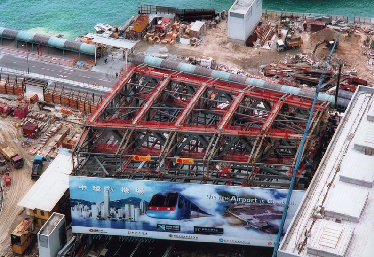

Steel prefabricated retail bridges |

|

|

Muck Hoist |

| Basic Information | |

| Location : | |

| Central, Hong Kong | |

| Building Type : | |

| Grade A commercial building | |

| Contract Period : | |

|

The One IFC and

South IFC Mall were completed in December 1998, |

|

| Developers : | |

| MTR Corporation Ltd. (Grantee of site), IFC Development Ltd., Sun Hung Kai Properties Ltd., Henderson Land Development Co. Ltd., The Hong Kong and China Gas Co. Ltd., Bank of China Group Investment Ltd. | |

| Architect : | |

| Cesar Pelli & Associates Inc., Rocco Design Ltd. | |

| Project Manager : | |

|

Central Waterfront Property Project

Management Co. Ltd. (jointly owned by : Sun Hung Kai Properties Co. Ltd.) Henderson Land Development Co. Ltd.) |

|

| Civil & Structural Engineer : | |

| Ove Arup & Partners | |

| E&M Engineer : | |

| J. Roger Preston Ltd. (Northern Site), Meinhardt (M&E) Ltd. (Southern Site) | |

| Quantity Surveyor : | |

| Levett & Bailey | |

| Structural Auditor : | |

|

Leslie E. Robertson Associates (New York) |

|

| E&M Auditor : | |

| Jaros, Baum & Bolles Consulting Engineers (New York) | |

| Main Contractor : | |

| E Man-Sanfield JV Construction Co. Ltd. | |

| Basement Construction Manager : | |

| Gammon Construction Ltd. | |

| Diaphragm Wall and Foundations : | |

| Aoki Corporation | |

| Retail Bridges : | |

| Gammon Construction Ltd. | |

| Structural Steel for IFCII : | |

| JV of NKK Corp. and Sumitomo Corp. | |

| Curtaim Wall for IFCII : | |

|

Permasteelisa HK Ltd. |

|

| Lifts : | |

| Otis Elevator Co. (HK) Ltd. | |

| Escalators : | |

| Schindler Lifts (HK) Ltd. | |

| Podium Curtain Wall Consultant : | |

| Arup Facade Engineering | |

| Office Tower Interior Designer : | |

| Hirsch Bedner Associates | |

| Landscape Consultant : | |

| Urbis International Ltd. | |

|

|

|

| . | |

| Overview | |

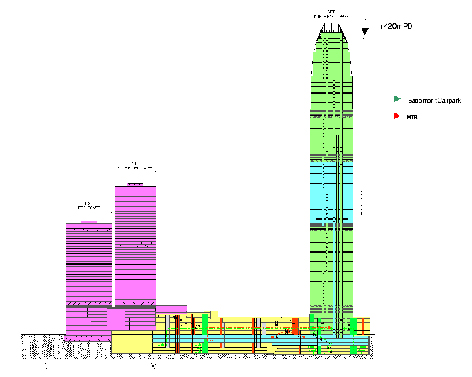

| The IFC complex located above the airport railway’s Hong Kong station comprises the completed One IFC 38-storey tower, the IFCII 88-storey tower, a 640,000sqft shopping mall and the Four Seasons Hotels. | |

|

|

|

|

|

|

One IFC : |

| The 38-storey One IFC building completed in December 1998, comprised 785,000sqft of office space. This building received a Quality Award Building in 2002. | |

|

|

The Four Seasons Hotel and Suites : |

| The Four Seasons Hotel will comprise of approximately 400 guest rooms with facilities including ballrooms, shops, banquet halls, conference rooms, swimming pools, health spa and restaurants. The four Seasons Suites will comprise of about 600 guest units. | |

|

|

IFCII : |

|

The IFCII 88-storey building is the third tallest building in the world with a height of 420m. The structure is made of concrete core, steel outriggers at three levels and large composite mega-columns. The tower was built with a 3 day-cycle floor construction. The traditional construction techniques were not used (apart from complex details) mainly because of the issues of vertical transportation of material supplies and waste generation, as well as the issue of time. The cost for traditional foundation would have cost about 130-150/sqft and for formworks (superstructure) about 150/m2, compared with a reduction of approximately 50% of the actual cost using innovative techniques. |

|

| On-site Facilities : | |

|

|

The huge project used a central project office (CPO) on-site to improve coordination of design and construction saving cost and time. |

|

|

The construction of a marine access at Pier 2 reduced traffic and environmental impact. |

|

|

The on-site concrete batching plant reduced cost and transportation. |

|

|

|

| Diaphragm Wall Cofferdam | |

|

|

| The construction of a 61.5 m diameter, 38 m deep, 1.5 m thick diaphragm wall cofferdam saved 9 months in North East Tower programme, and reduced cost. | |

|

|

|

|

|

|

|

| Top Down Construction Technique | |

| It was used for the 6 level basement minimizing movement of existing station. | |

|

|

|

|

|

|

| Sources | |

|

|

Hong Kong Station Development International Finance Centre Power Point Presentation, Central Waterfront Property Project Management Co. Ltd. |

|

|

China Building Development, issue No.1, 2002. |

|

|

Construction & Contract News, 2001 No.4, p40-43. |

|

|

Building Journal Hong Kong China, April 2002, p60-61. |

|

|

Building Journal Hong Kong China, May 2001, p14. |

|

|

www.skyscrapers.com |

|

|

|

| Areas | |

|

|

Southern Site : 85,063 m2 |

|

One IFC : 72,880 m2 |

|

| IFC mall : 12,183 m2 | |

|

|

Northern Site : 330,837 m2 |

| IFC2 : 181,310 m2 | |

| Retail : 47,277 m2 | |

| Hotel : 102,250 m2 | |

|

|

Grand Total : 415,900 m2 |

|

|

Public Open Space : 13,000 m2 |

|

|

Development Carparks : 1,341 spaces |

|

|

AEL Carparks : 450 spaces |

| Concrete Core | |

|

|

| The concrete core was built with hydraulic climbform system saving time and ensuring quality. The same formwork was used for the whole concrete core reducing the generation of construction waste on-site. Traditional techniques would have been difficult considering the issue of vertical transportation of materials and wastes, as well as time consuming. Due to the immense size of the wall sections, two sets of climbform were used in staggered stages for casting the concrete core. Tie members linked the two portions into a rigid central structure. At the lower levels, the core wall is 1.5 m thick. | |

|

|

|

|

|

| Large Composite Mega-columns | |

|

|

|

The steel and concrete composite mega-columns were cast with a specially designed form system. The form was mounted with anchor bolts on to the lower part of the column. Hydraulic jacks inside the central post could lift the form when the concreting of the lower parts was completed. |

|

| Steel Permanent Formwork for Slabs (Condek) | |

|

|

|

Steel permanent formwork was used for the slabs saving time (hoisting and removing time) and reducing on-site waste generation. Once the permanent formwork and the reinforcement bars installed 1.25 mm thick concrete was poured (pumping system and robotics). |

|

| Prefabricated Staircases | |

|

|

|

The stairs were fabricated in, and delivered to site by sea. The prefabrication techniques saved time, cost and ensured quality. |

|

| Prefabricated Curtain Wall | |

|

|

|

Permasteelisa is responsible for the design engineering, supply, fabrication, assembly and installation of the composite curtain wall system, glass walls and glass canopies, glazed entrances and revolving doors at the podium levels as well as the aluminum cladding on the roof fins at the top of the building.

The project

includes: |

|

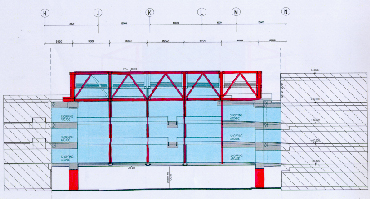

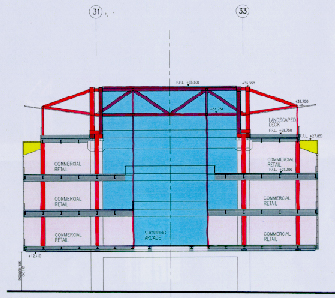

| Retail Bridges | |

|

|

|

|

| The steel structure of the retail bridges was prefabricated in Southern China and delivered to the site by sea. Bridges were erected within three months before road openings. | |

| Construction Materials | |

|

|

Excavated Materials : 1,000,000 m3 |

|

|

Concrete : 500,000 m3 |

|

|

Reinforcement : 100,000 tonnes |

|

|

Structural Steel : 38,000 tonnes |

|

Waste Management |

|

|

|

| The excavated waste arising from the construction of the 6-storey basement, was transported by barges to the Disney reclamation site in Lantau Island. | |

| Waste arising from construction (mainly packaging, concrete and timber) which was about 6 trucks a day were transported to landfills. The amount of waste generated on-site was reduced by the use of prefabrication techniques. | |

|

|

|

| Contact of Contractor | |

| E Man-Sanfield JV Construction Co. Ltd. | |

|

|

|

| 3D Animations | |

|

|

jack-up and jumpform. |

| Take a look of jack-up movie | |

| Take a look of jumpform movie | |

|

|

|