|

|

| Notable Features | |

|

|

Precast facades |

|

|

Semi-precast slabs |

|

|

Steel large panel formwork |

|

|

Dry wall internal partition |

|

|

Bathroom tiles |

| Basic Information | |

| Location: | |

|

8-12 Shelter Street,

Causeway Bay, Hong Kong. |

|

| Building Type : | |

| Hotel | |

| Contract Period: | |

|

19 months of construction, completed in 2001 |

|

| Contract Sum : | |

| Site Area : | |

| 611m2 | |

| Gross Floor Area : | |

| Total Construction Floor Area : | |

| m2 | |

| Typical Floor Area : | |

| m2 | |

| Client : | |

| Paul Y-ITC Construction Holdings Ltd. | |

| Architect : | |

| Cartesian Architects Ltd. | |

| E&M Consultant : | |

| Paul Y-ITC (E&M) Contractors Ltd. | |

| Design & Build Contractor : | |

| Paul Y-ITC General Contractors Ltd. | |

| Interior Design : | |

| Paul Y-ITC Interior Contractors Ltd. | |

|

|

|

| . | |

| Overview | |

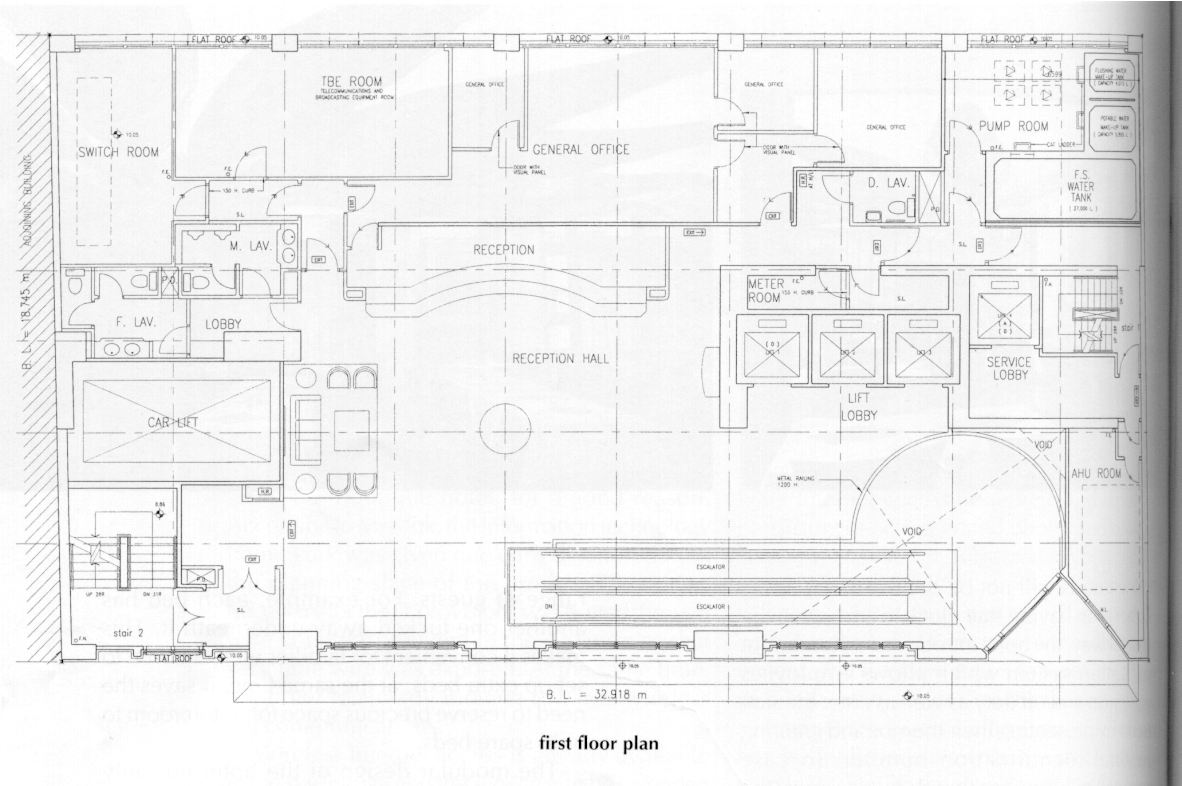

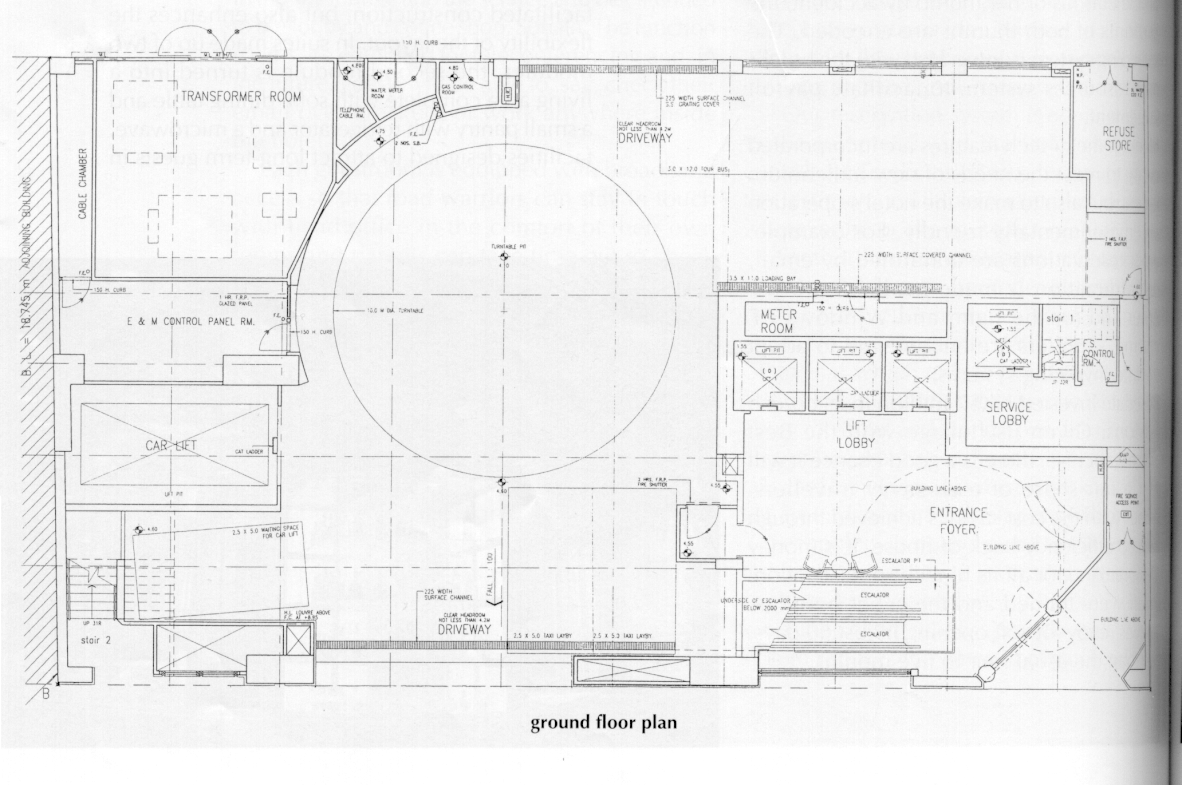

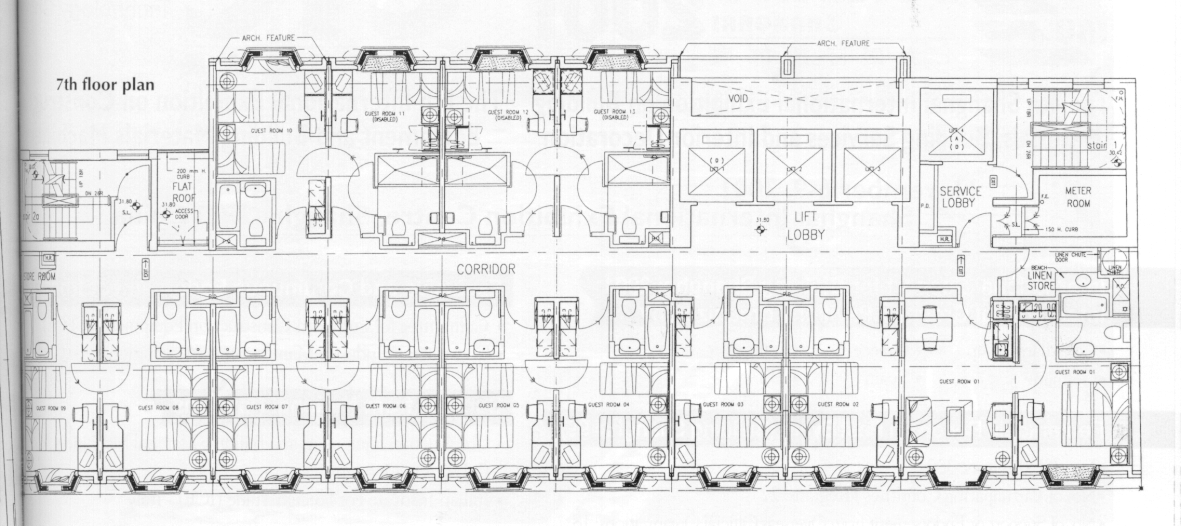

| The 33-storey building which comprises 274 rooms, was designed and built by the same company, Paul Y-ITC Group. This approach allowed the designer and contractor to work out on a design based on buildability promoting the use of precast construction. Apart from non-typical elements on the top floor and the podium, the hotel was built by 322 standard modules with semi-precast slabs and precast façade units. The ground floor is mainly for vehicular accesses, with a lobby on the first floor. | |

|

|

|

|

|

|

| Precast Facades |

| The façade units were fabricated at Paul Y-ITC’s factory in Yuen Long. Two types of steel moulds were used for casting end modules and middle modules. Ceramic tiles and glazing were also affixed at the factory. The glazing was tested at the factory before transportation to the site for installation. |

| The cost which was more expensive than timber formwork, was justified by the number of modules required. The steel mould could be used over and over again. |

|

|

| Steel Large Panel Formworks |

| Steel large panel formworks were used to cast the structural walls in-situ. |

|

|

|

|

| Semi-precast Slabs |

|

The semi-precast slabs were hoisted and positioned over the walls and façade units to form the lower layer of the floor slab. They served as permanent formworks, part of the permanent structure. |

| The advantage is that both time and labour were saved because there was no need to dismantle the formwork. |

|

|

| Dry Wall Internal Partitions |

| Dry wall system was used for the internal partitions. The lightweight material reduced the dead load imposed on the structure, and wet trades were avoided. Also, it provided a smooth wall finish. |

|

|

| Cost |

|

The risk associated with working outdoors is usually taken into account in the tender price of contractors. Since these risks were effectively removed by the construction method used, the prices were reduced allowing cost savings of 3-4%. |

|

|