|

|

| Notable Features | |

|

|

Precast coffered slab units (steel formworks) |

|

|

Steel shutters for in-situ edge beams |

|

|

Steel structure for atrium |

|

|

Raised floor system |

|

|

|

| Basic Information | |

| Location : | |

| Edinburgh Part, Edinburgh, UK | |

| Building Type : | |

| Office | |

| Contract Period : | |

|

08/1994 - 09/1995 |

|

| Client : | |

| John Menzies (UK) | |

| Project Manager : | |

| Buro Four Project Services | |

| Architect : | |

| Bennetts Associates Architects | |

| Structural Engineer : | |

| Curtins Consulting | |

| M&E Services Engineer : | |

|

Blyth & Blyth Ltd. |

|

| Quantity Surveyor : | |

| Banks Wood & Partners | |

| Liaison Architect : | |

| Campbell & Arnott Ltd. | |

| Landscape Architect : | |

| Ian White Associates | |

| Acoustic Consultants : | |

| Arup Acoustics | |

| Masterplan Architect : | |

| Richard Meier & Partners | |

| Management Contractor : | |

| Bovis Scotland | |

|

|

|

| . | |

| Overview | |

|

|

|

|

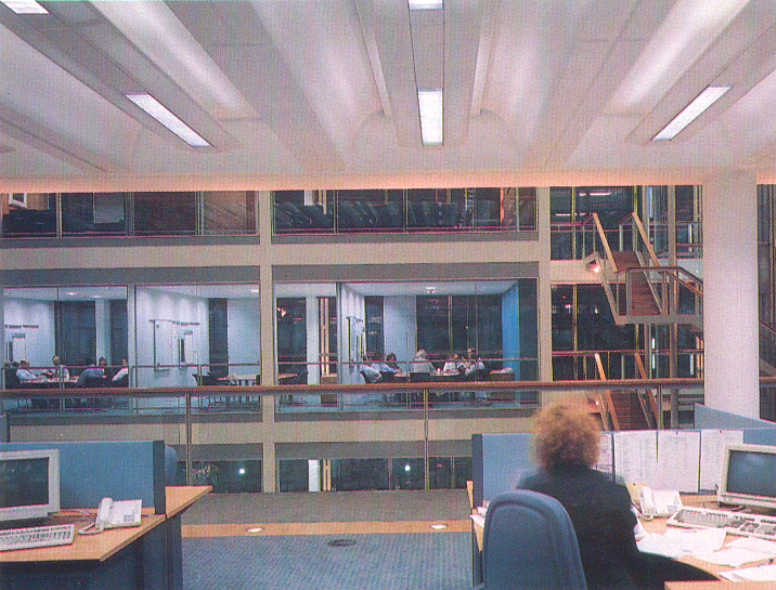

| The building issues considered were flexibility, good communications and environmental conditions. Within the resulting workplace, which is generally composed of 12m wide floor-plates, the three-storey building adopts a compact quadrangle form, with circulation balconies around the inner perimeter and a partly glazed roof covering the central space. | |

|

|

|

| Structures | |

|

|

| Flexibility consideration resulted in a 12m clear floor span from the external building perimeter to the perimeter of the atrium. | |

|

|

|

| Sources | |

|

|

www.ajspecification.com |

|

|

The Architects’ Journal, 30 November 1995, pp29-39. |

|

|

|

| Precast Coffered Slab Units |

|

|

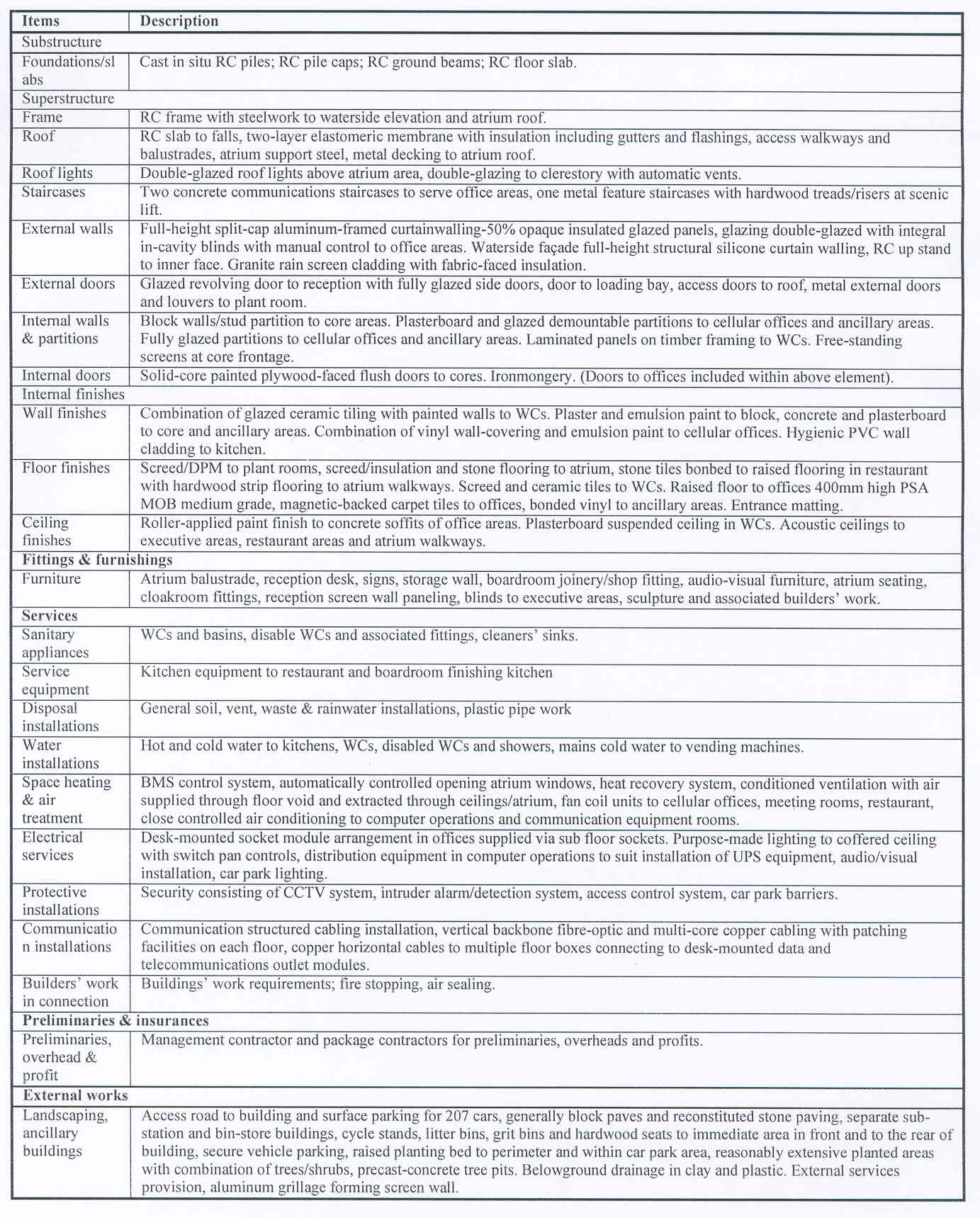

| Reduction in the on-site program period was possible with a hybrid in-situ concrete frame with precast coffered slab units. The coffered slab units, each weighing 11 tones, were manufactured off-site using steel moulds. The sequence of frame construction was to erect the 400mm diameter columns first, then place the 12m long precast coffer units on temporary supports. It was followed by the casting of the in-situ perimeter ring beam and structural topping in one operation, to tie the precast elements together. |

|

|

| Steel Shutters for In-situ Edge Beams |

| The use of purpose-made steel shutters, both for on-site for in-situ edge beams, and off-site for the coffer units, enhanced the quality of finish and speed of construction. |

|

|

| Roof Steel Structure for the Atrium |

|

The roof steelwork over the atrium comprises slender steel trusses at 6m centers spanning the 12m width of the atrium. The top and bottom chords are formed from back-to-back steel channel sections with 32mm diameter tie rods forming the internal bracing. |

|

|

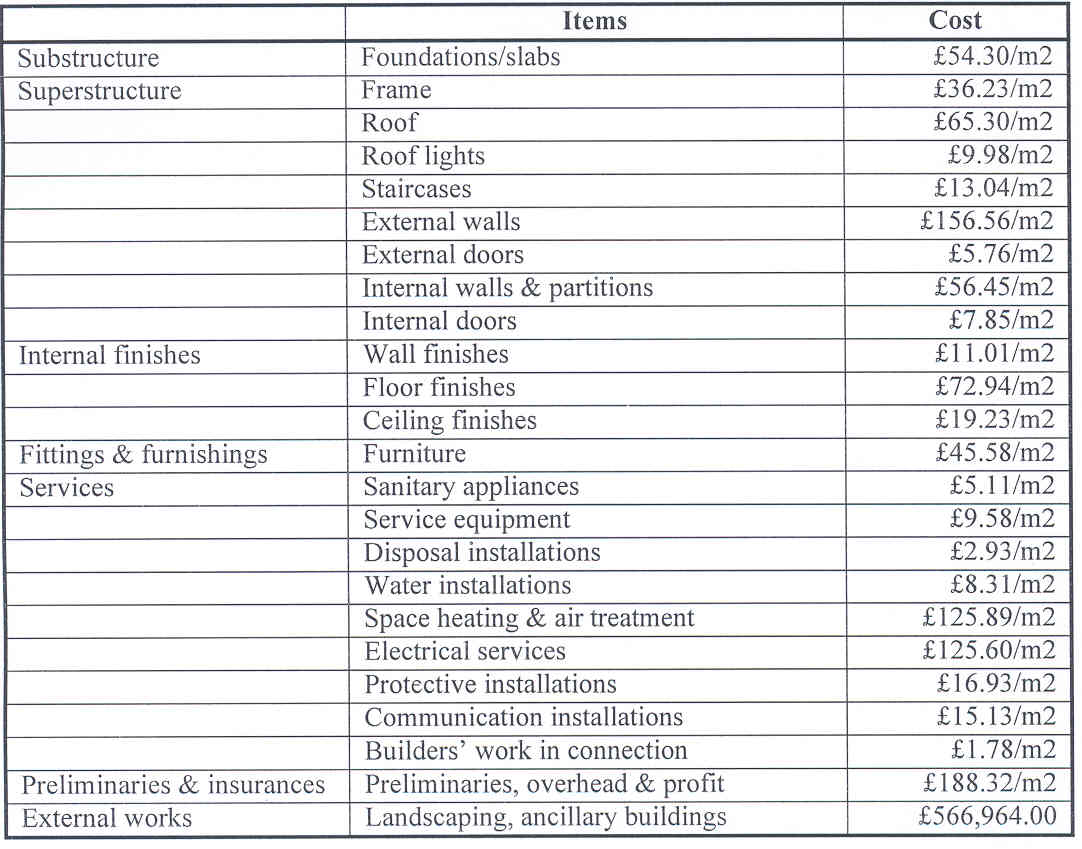

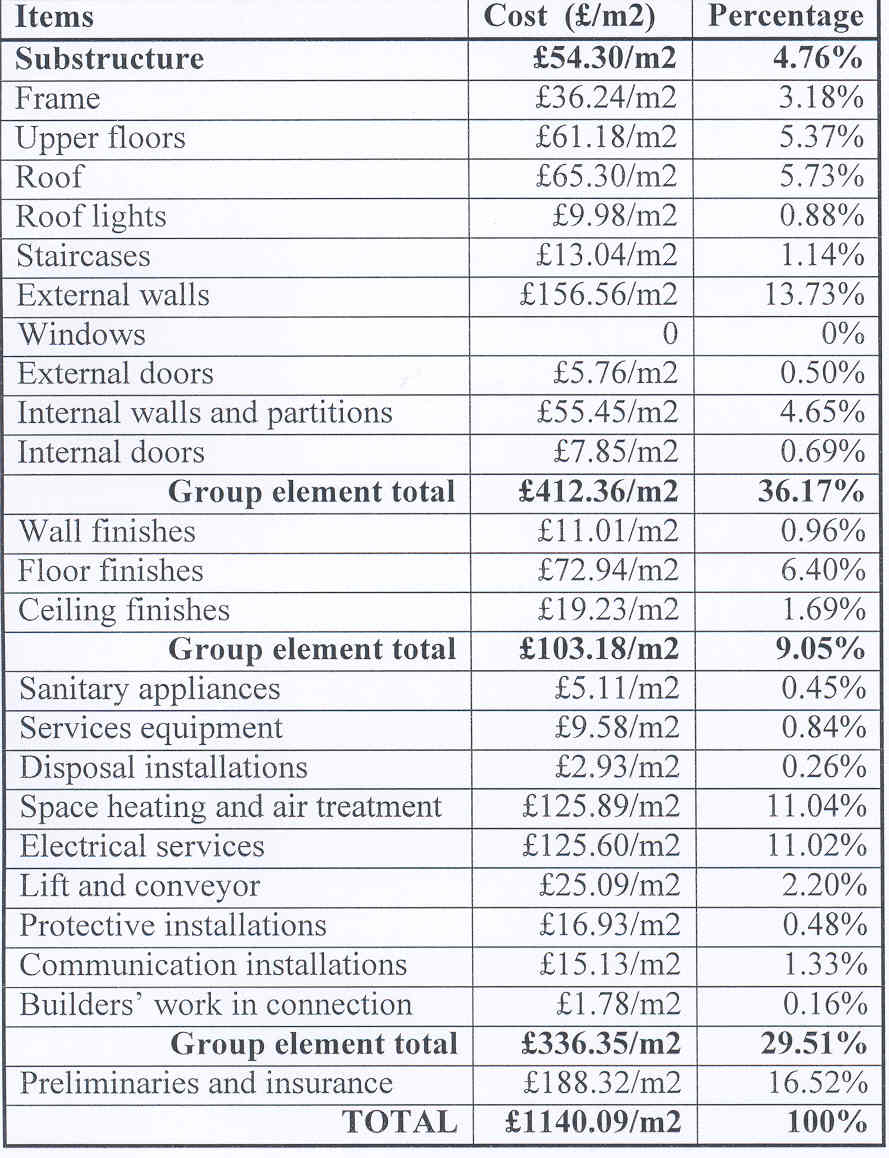

| Cost Analysis |

| The cost analysis is based on post-tender resolution costs, which would most accurately represent an analysis of tender under a traditional form of contract. The overall figure of £1140/m2 (low energy design), including fit-out, is well within the range of costs for similar buildings. |

|

|

| Cost Summary |

|

|

|