|

|

| Notable Features | |

|

|

Precast concrete structure |

|

|

Precast cladding panels |

|

|

Raised floor system |

|

|

|

| Basic Information | |

| Location : | |

| Victoria Quay, Leith, Edinburgh, UK | |

| Building Type : | |

| Office | |

| Contract Period : | |

|

24 months; construction; 20 months |

|

| Gross Floor Area : | |

| 45,000m2 | |

| Client : | |

| Victoria Quay Ltd. | |

| Architect : | |

| RMJM Ltd. | |

| Structural Engineer : | |

| RMJM Ltd. | |

| Services Engineer : | |

| RMJM Ltd. | |

| Quantity Surveyor : | |

| Gardiner & Theobald | |

| Interior Design : | |

| RMJM Ltd. | |

| Landscape Architect : | |

| RMJM Ltd. | |

| Main Contractor : | |

| Trafalgar House Construction Management | |

|

|

|

| . | |

| Overview | |

|

|

|

|

| The building comprises office space for about 1500 Scottish Office staff. A simple ladder plan accommodates 3 linked departmental blocks on 4 floors, each focused around an atrium. The atrium in the central block is punctuated by the entrance rotunda rising above the rest of the building. On the south façade, a 2-storey colonnade runs along the entire length of the building providing a covered pedestrian route. The project has achieved a BREEAM rating of “very good” for its energy consideration. | |

|

|

|

| Awards | |

|

|

RIAS Regeneration Design Award, 1995. |

|

|

|

| Sources and Photos | |

|

|

www.trentconcrete.co.uk/case_studies/ scot_off_leith_edinburgh.htm |

|

|

www.ajspecification.com |

|

|

The Architects’ Journal, 7 December 1995, pp29-37. |

|

|

|

| The Structure |

|

| The need for thermal mass is achieved through a concrete frame and ribbed-floor construction, with the precast concrete providing the desired level of finish. The line loading from the 3rd floor setbacks is minimized through the use of structural steelwork and allows the depths of the main structural frame beams to be maintained. The 15m spans forming the rungs are achieved by using pre-stressed precast-concrete floor beams. |

| The repetitive structural system favoured prefabrication construction. Precast “double tee” floor units have been adopted as a primary structural system. The basic precast concrete module of 1.5m, reflecting the planning grid has been detailed to achieve satisfactory joints between precast units (in-situ concrete infills and fire-resistant sealants). The in-situ concrete columns in the rotunda and core were built during the setting up of the prefabrication system. |

| The precast concrete structure and cladding allowed faster construction (20 months program). 40,000m2 of structure and cladding were erected in 26 weeks. |

|

|

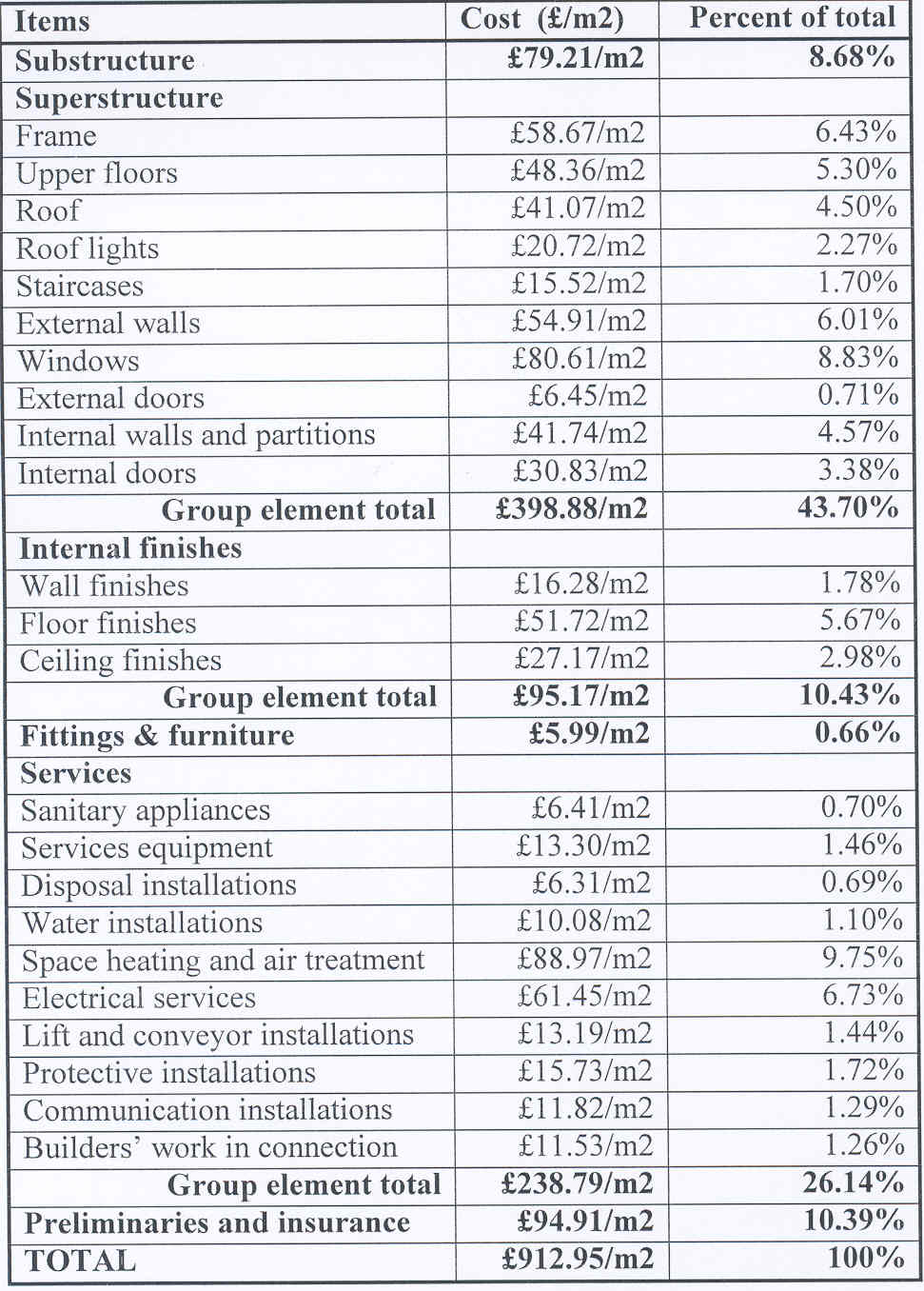

| Cost Analysis |

|

|

| Cost Summary |

|

|

|