| Assembly |

| |

|

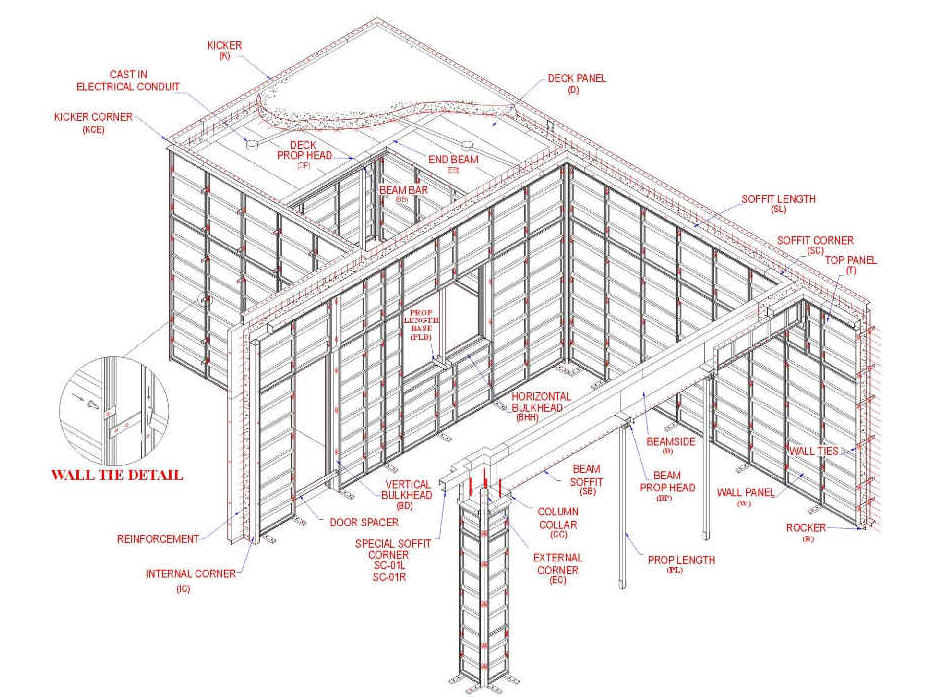

The simplicity of Aluminium Formwork and the repetitive nature of the

assembly process make it possible to accurately programme

construction sequences and thus cycle times well in advance. In

addition this enables unskilled labour to work with the Formwork

therefore reducing the burden on skilled labour when this is in

short supply.

On leaving the factory all panels are clearly labelled to

ensure that they are easily identifiable on site and can be smoothly

fitted together using the formwork modulation drawings.

|

|

|

| |

|

|

| Pin and Wedge System |

| |

| The panels

are held in position by a simple pin and wedge system that

passes through holes in the outside rib of each panel. The

panels fit precisely, simply and securely and require no

bracing. Buildings can be constructed quickly and easily by

unskilled labour with a hammer being the only tool required.

Once the panels have been numbered, measuring is not

necessary. As the erection process is manual, tower cranes are

freed up and can concentrate on other handling operations. The

result is a typical 4 to 5 day cycle for floor to floor

construction. |

|

| |

|

|

| |

|

|

| Quick Strip Prop Head |

| |

| One of the

principal technical features which enables this speed to be

attained using a single set of formwork panels is the unique V

shaped prop head which allows the 'quick strip' to take place

whilst leaving the propping undisturbed. The deck panels can

therefore be reused immediately. |

|

| |

|

|

| |

|

|

| Speed and Quality |

| |

| The in-situ construction of all walls and

partitions reduces the requirement for follow-on wet trades.

The concrete surface finish produced with the aluminium forms

allows achievement of a high quality wall finish without the

need for extensive plastering. Doors and windows are formed in

position, with this high degree of precision items such as

door and window frames can be directly installed on site with

minimal re-sizing required. |

|

| |

|

|

| |

|

High quality Aluminium Formwork panels ensure

consistency of dimensions. On the removal of the Formwork mould, a high quality

concrete finish is produced to accurate tolerances and

verticality. The high tolerance of the finish means that no

further plastering is required. Typically a 3mm to 4mm skim

coat is applied internally prior to finishing and a 6 mm build

up coat prior to laying

tiles.

|

| |

|

|

| Contact of Supplier

|

| |

| VSL

Hong Kong Limited

|

| 3/F

Stelux House, 698 Prince Edward Road East, San Po Kong, Kowloon,

Hong Kong.

|

| Tel:

(852) 2590 2288

|

| Fax:

(852) 2590 0290

|

|

|

|

|

|

![]() |

|

| Formwork System Description |

| |

| The basic element of the

Formwork is the panel which is an extruded aluminium rail

section, welded to an aluminium sheet. This produces a

lightweight panel with an excellent stiffness to weight ratio,

yielding minimal deflections under concrete loading. Panels

are manufactured in the size and shape to suit the

requirements of specific projects.

The panels are made

from a high strength aluminium alloy with a 4mm thick skin

plate and a 6mm thick ribbing behind to stiffen the panels.

The panels are manufactured within factory environment. Once

assembled they are subjected to a trial erection in order to

eliminate any dimensional or on site problems. |

|

|

|

| Formwork Structure |

| |

| Architectural details are

incorporated during the design and manufacture of the aluminium panels

and can be designed for any condition such as bay windows, stairs, balconies and

special architectural

features. The accurate regular dimensions achieved with the

aluminium

formwork system enable pre-fabrication of cast in items, door and

window frames and electrical and mechanical components. |

|

| |

|

|

| |

|

|

|

| |

| |

Timber

Formwork |

System

Formwork |

|

Material

|

Timber and Plywood

|

All

Aluminium

|

|

Durability

|

20

times

|

120-150

times

|

|

Wastage

|

Yes

|

No

|

|

Quality

|

Subject

to Workmanship

|

Good

|

|

Labour

|

Skilled

|

Unskilled

|

|

Flexibility

|

More

|

Less

|

|

Cost

|

HK$100-140/m2

|

HK$140-180/m2

|

|

|

|

|

|