| Notable Features |

| |

|

Construction waste

reduction/recycling program |

|

Reduced Construction waste due

to use of factory manufactured aluminium formwork panels |

|

Application of

value engineering in terms of slab and wall formwork |

|

Use of system

formwork |

|

Use of bay windows

and A/C hoods |

|

Aluminium formwork

panels were

used for casting the structural shear walls |

|

Reuse of aluminium

formwork panels |

|

V-shaped prop head

system |

| Basic

Information |

| |

|

Location: Tseung

Kwan O |

|

Site Area: 500,000

sq ft |

|

Building Type: 15

luxurious residential towers in three phases |

|

Contract Period:

750 days for phase 1 |

|

Facilities: Club

house, swimming pool, tennis court, children's play ground, car park

etc. |

|

Client: Arrowtown Assets Limited |

|

Architect: Wong

Tung & Partners Ltd. |

|

Quantity Surveyor: Davis

Langon & Seah Hong kong Ltd. |

|

Structural Engineer:

Joseph Chow & Partners Ltd. |

|

E&M

Consultant: Meinhardt (M&E) Ltd. |

|

Main Contractor: Sanfield

Building Contractors Ltd. |

|

Building costs: HK$

1600 million for phase 1 |

| Overview |

| |

|

The Tseung Kwan O TKOTL 55

development, named as Ocean Shore with a site area of over 500,000

square feet, consisted of 15 luxurious residential towers to be

constructed in 3 phases.

Following to the client's requirement,

the architect emphasized his design to capture the greenery

surrounded

either along the hillside or the lush plantation of the landscaped

podium garden. A 3 levels podium structure was therefore designed to

provide space for various facilities including the clubhouse,

swimming pool, tennis court, children's play ground, car park

etc.

It was the developer's vision

to provide the best not only the large scale master layout plan but

also the quality of the apartment to the residents lived there.

| Plastering and Finishing

|

| |

| The main

advantage of aluminium formwork was good alignment and

verticality with good concrete finish surface which minimised

the cost on plastering and finish work. High quality Aluminium Formwork

Panels ensure

consistency of dimensions. On the removal of the formwork mould, a high quality

concrete finish was produced to accurate tolerances and

verticality. The high tolerance of the finish means that no

thick plastering was required. Typically a 3mm to 4mm skim

coat was applied internally prior to finishing and a 6 mm build

up coat prior to laying

tiles. |

|

| |

|

|

| Contact

of Contractor

|

| |

| Sanfield

Building Contractors Ltd.

|

| 44/F,

Sun Hung Kai Center,

|

| 30

Harcourt Road, Wanchai,

Hong Kong.

|

| Tel:

(852) 2827 8111

|

| Fax:

(852) 2827 0717

|

|

|

|

|

|

|

|

![]() |

|

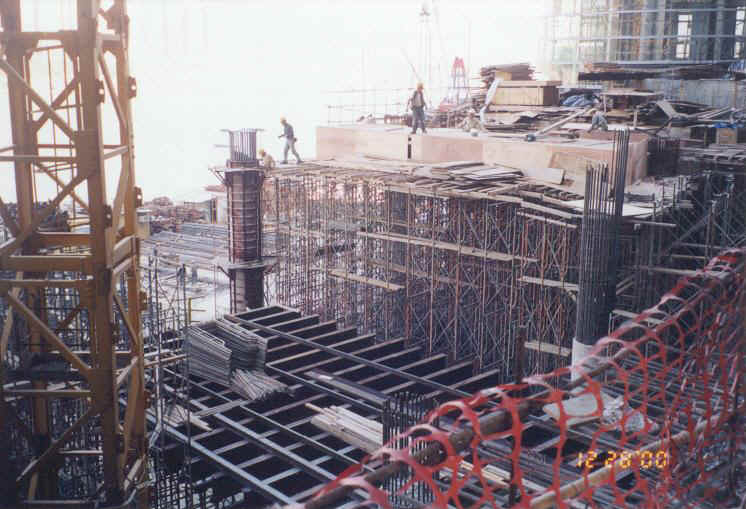

| Slab and Wall System |

| |

| It had been the

client's intention to use system formwork for

a better quality concrete finish and good alignment and verticality.

However with the complex architectural features, bay windows and A/C

hoods etc. were adopted in this project, the use of large steel panel or

precast concrete panel was not an option for the construction

in this project. |

| |

| The engineer was requested to

explore the possibility of using aluminium handset system formwork on

both technical and cost effectiveness requirements. A simple handset

aluminium formwork was finally chosen to use on

three residential blocks of phase 1 and majority of the aluminium

formwork panels will be reused on the residential blocks of phase 2. The advantages of

aluminium formwork are:

|

| |

|

Good alignment and verticality |

|

High finish

quality |

|

No tower

crane required |

|

Require

unskilled

labour force |

|

Environmental

friendly |

|

Speedy and

economical |

|

Earlier

stripping of forms |

|

| |

Timber

Formwork |

System

Formwork |

|

Material

|

Timber and Plywood

|

All

Aluminium

|

|

Durability

|

20

times

|

120-150

times

|

|

Wastage

|

Yes

|

No

|

|

Quality

|

Subject

to Workmanship

|

Good

|

|

Labour

|

Skilled

|

Unskilled

|

|

Flexibility

|

More

|

Less

|

|

Cost

|

HK$100-140/m2

|

HK$140-180/m2

|

|

| |

|

|

| Steel

Column Formwork |

| |

| Steel column

formwork was used to construct the large circular column as shown in

the figure below. |

| |

|

|

| |

| Steel forms

are very durable and can be recycled many times. Steel forms produce

a better quality concrete product. |

| |

|

|

| |

|

|

| Waste Management |

| |

|

Material control |

|

Reusable material adopted-aluminium

formwork |

|

Surplus steel bars

were stored for

reuse |

|

Job-site

recycling |

|

|

|