Flooring

| . |

|

A slab is called semi-precast when the lower portion of the floor slab is prefabricated at the factory. It is then hoisted and set into position on site and acts also as shuttering to receive the top layer of floor slab which is cast in-situ. The whole slab is a permanent composite of precast and in-situ concrete. As for precast facades, boxing-outs are cast at the designed locations during slab fabrication at the factory. The subsequent services installation also becomes more efficient. |

The lower layer of semi-precast slab

|

However, it has been reported by contractor that the semi-precast slab is not suitable for large span structure. Careful handling is required, otherwise cracks would be appeared on the slab. |

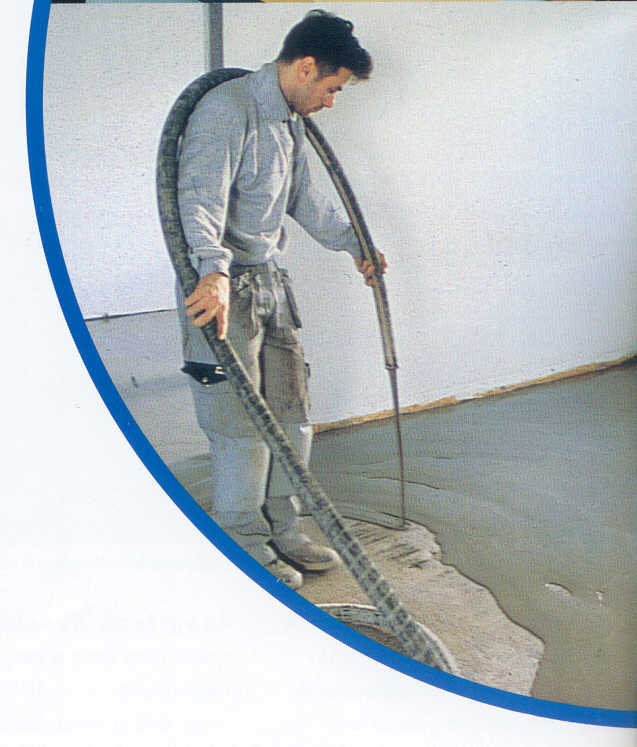

The unique Self-Levelling Flooring System is a reliable, self-flowing and self-smoothing cementitious system for application directly onto all kinds of concrete, wooden, tile and terrazzo bases. It has been specially developed as a complete system, taking into account every aspect of floor preparation from start to finish. The system accomplish with a minimum of disruption and achieve high quality results, time after time. It is so efficient that contractors can, in the same amount of time and for a fraction of the labour costs, finish up to ten times the flow area they could manage using traditional methods. The end results are hard-wearing, long-lasting floor carried out quickly, economically and with a minimum of disruption.

Kowloon Bay, Kowloon, Hong Kong

Fax: (852) 2758 2263

|

|

Cheung Sha Wan West Phase-II, Hong Kong |

|

|

Tseung

Kwan O Area 73A Phase-II, Hong Kong |

|

|

Tseung Kwan O Area 74 Phase-IV, Hong Kong |

|

|

Golden Trend Construction Limited Bai Sha Shui Village, Long Xi, Long Gang District, Shenzhen, P.R.C. Tel: 2380 9605 Fax:2414 5766 |

|

Sun Fook Kong Construction (Concrete Products) Limited Shu Gang Road, Shekou District, Shenzhen, Guangdong, PRC Tel: 2828 1688 Fax: 2827 6275 |

|

|

Lamma Rock Products Limited Architectural Member Engineering Company Building, Huang Qi Town, Nanhai, Guangdong Province, P.R.C. Tel: 2398 4018 Fax: 2789 1040 |

|

Unicon Concrete Products (Hong Kong) Limited D.D. 95, Lot No. 9-12, Ho Sheung Heung, Sheung Shui, N.T., Hong Kong Tel: 2477 0867 Fax: 2478 6220 |

|

|

Main Kind Industrial Limited Xiangyuan Village, Longgang Pingdi Town, Shenzhen, Guangdong, P.R.C. Tel: 2336 1262 Fax: 2336 1077 |

|

Unicon Concrete Products (Hong Kong) Limited Heng Li, Dongguan, P.R.C. Tel: 2477 0867 Fax: 2478 6220 |

|

|

Orientfunds Precast Limited Fu Lu Sha Region, Sha Tian Town, Dongguan, Guangdong, P.R.C. Tel: 2546 2612 Fax: 2517 0873 |

|

Wai Hing Construction Materials Company Limited West Nan Gang Road, Nan Gang, Huang Pu, Guangzhou, P.R.C. Tel: 2715 6942 Fax: 2713 0762 |

|

|

Shen Zhen Sun Wah Concrete Products Company Limited Niu Shing Village, Nam Shan District, Shenzhen, P.R.C. Tel: 2893 4648 Fax: 2494 7251 |

|

Yau Lee Wah Concrete Precast Products Company Limited Qinghu Industrial District, Heping East Road, Longhua Town, Baoan Qu, Shenzhen, Guangdong, P.R.C. Tel: 2753 4388 Fax: 2753 4300 |