Tiling Work

|

Precast cladding is a new construction method for tiling works. The cladding panels are manufactured in the precast factory. The production processes are: place wall tiles onto the steel mould face down, pour lightweight concrete onto the back of the tiles, and demould after hardening The tiles are thus cast integrably with the lightweight concrete and no traditional tile fixing by cement mortar or adhesive is required. |

|

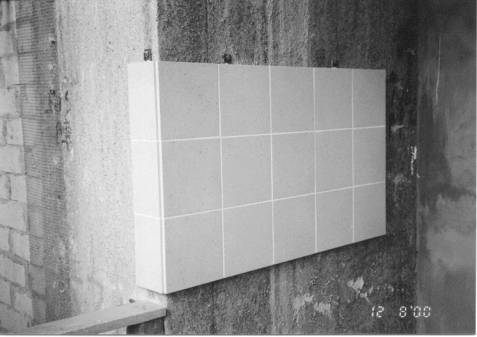

At the construction site, the positions for holding brackets will be set out, and cladding panels leveled and fixed. Figure below shows the fixing of the cladding panels. |

Fixing of cladding panel by brackets

|

Reduced quality of skilled labour |

|

|

Less wastage – wet trades on site such as plastering and tiling are reduced |

|

|

Less waste produced |

|

|

Better quality |

|

|

Flexible time control – no setting and curing time are needed on site |

|

|

A clean and safe working environment is achieved |

| Tseung

Kwan O Area 73A Phase-II, Hong Kong |