|

Scaffolding |

|

| |

|

|

|

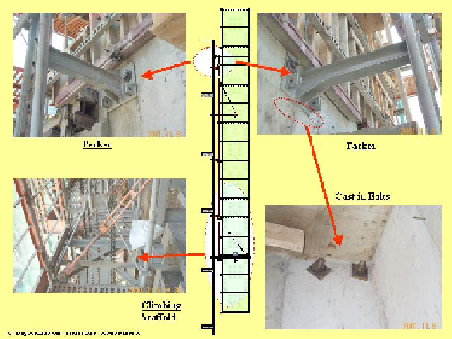

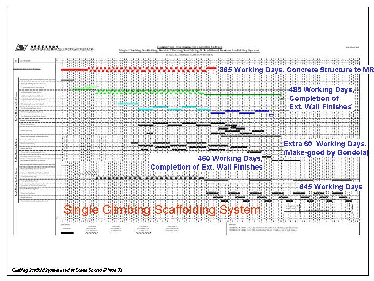

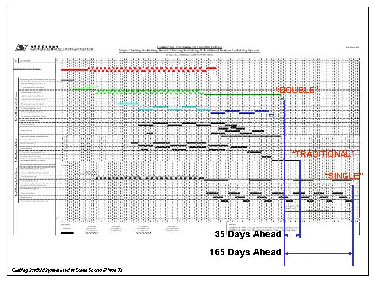

Climbing

Scaffolding System |

Metal-Bamboo Matrix System

Scaffold (MBMSS) |

|

| |

|

|

|

|

Climbing

Scaffolding System |

|

|

|

|

|

|

|

|

|

|

(Source

: Wui Fai Holdings Ltd) |

|

|

|

|

|

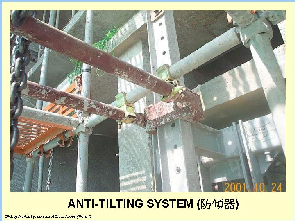

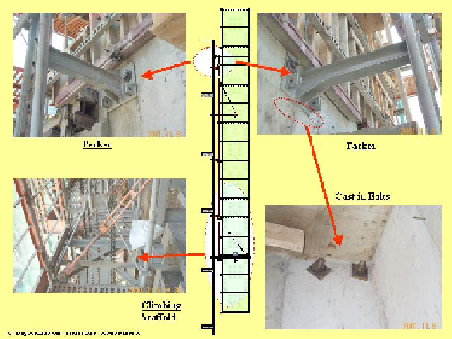

The

Climbing Scaffold is a computerized self-climbing system scaffold for

the

construction of high-rise buildings. Its main components include a

computerized control system, an anti-tiling and fall arrest system, an

electric chain block, a multi-functional steel scaffolding system. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Computerized control system

|

|

|

|

|

|

|

|

|

|

|

|

Function includes control of partial or full lifting upward or downward.

Function includes control of partial or full lifting upward or downward. |

|

|

Overloading warning system with alarm to minimize risks.

Overloading warning system with alarm to minimize risks. |

|

|

Easily adjustable height of the lift.

Easily adjustable height of the lift. |

|

|

|

|

|

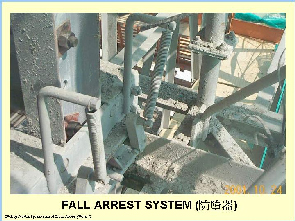

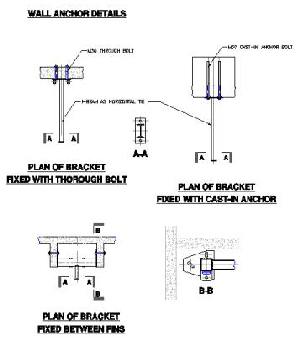

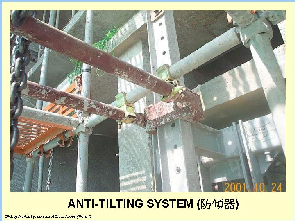

Double guide rails with anti-tilting and fall-arrest system

|

|

|

|

|

|

|

|

|

|

|

|

Keeps the

climbing scaffolding stable when lifting and lowering. Keeps the

climbing scaffolding stable when lifting and lowering. |

|

|

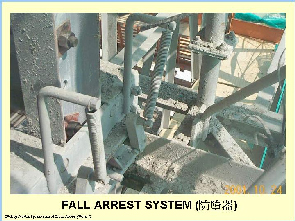

Equipped

with a fall-arrest system to enhance safety. Equipped

with a fall-arrest system to enhance safety. |

|

|

|

|

|

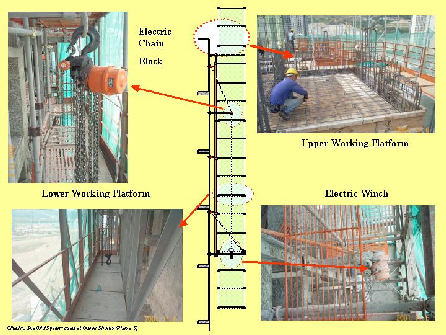

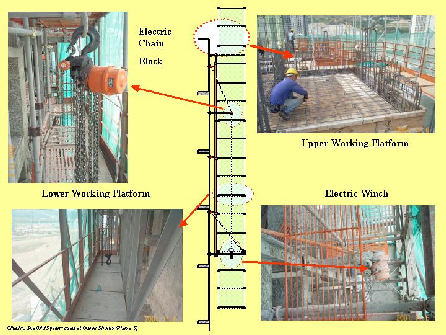

Electric chain block

|

|

|

|

|

|

|

|

|

|

|

|

Equipped

with an anti-skid system. Equipped

with an anti-skid system. |

|

|

High

strength chain support with a capacity of over 15MT. High

strength chain support with a capacity of over 15MT. |

|

|

|

|

|

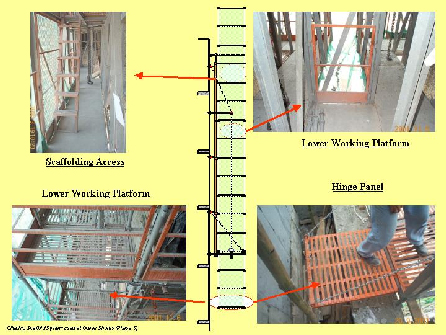

Multi-functional steel scaffolding

|

|

|

Ease of

assembly for different heights, floors and types of structure. Ease of

assembly for different heights, floors and types of structure. |

|

|

|

|

|

|

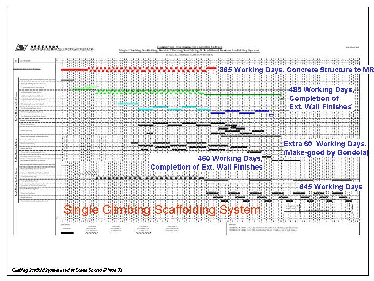

Advantages of Climbing Scaffolding System |

|

|

|

|

|

|

|

Ease of construction

|

|

|

Fast

concreting cycle Fast

concreting cycle |

|

|

Suits

different heights and building shapes (curve, corner, balcony shapes,

etc.), Suits

different heights and building shapes (curve, corner, balcony shapes,

etc.),

and slopes. |

|

|

|

|

|

Economical

|

|

|

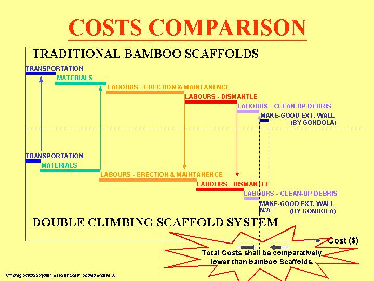

Only

require one time installation and can be used repeatedly Only

require one time installation and can be used repeatedly |

|

|

Shorten

construction time. Shorten

construction time. |

|

|

Reduces

60% of material used when compared with traditional scaffoldings. Reduces

60% of material used when compared with traditional scaffoldings. |

|

|

Reduces

costs. Reduces

costs. |

|

|

|

|

|

Safety

|

|

|

Built-in

safety systems ensure safe working environment (warning system for Built-in

safety systems ensure safe working environment (warning system for

overloading,

anti-tilting and fall-arrest system, etc.). |

|

|

|

|

|

Ease of operation

|

|

|

Require

simple assembly and setting up. Require

simple assembly and setting up. |

|

|

Ease

of lifting upward and downward. Ease

of lifting upward and downward. |

|

|

|

|

|

Reusable

|

|

|

Parts

are standardized and reusable. Parts

are standardized and reusable. |

|

|

|

|

|

|

|

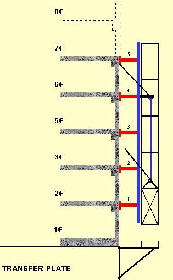

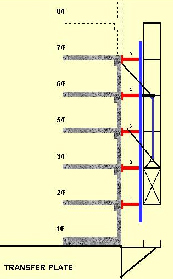

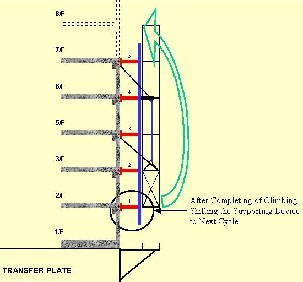

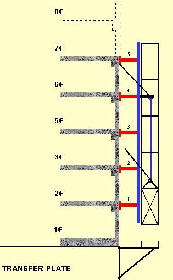

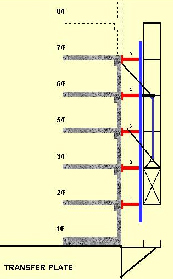

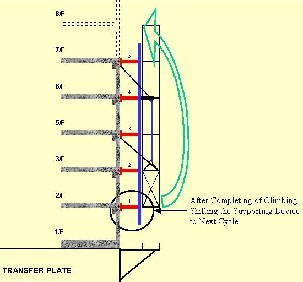

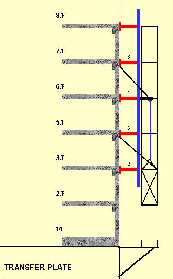

Climbing Scaffolding Procedure |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

After

installation of the system, the climbing scaffolding moves upward. After

completing the 1st climbing cycle, the shifting of the

supporting device to the next cycle can be executed (refer to figures). |

|

|

|

|

|

|

|

|

|

(refer to

figure) |

|

|

|

|

|

|

|

|

|

|

|

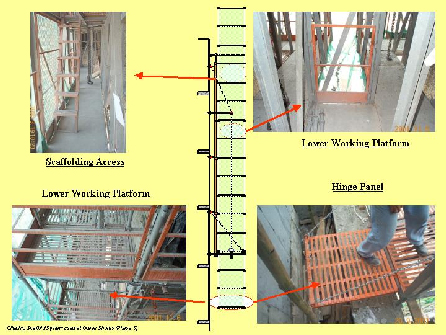

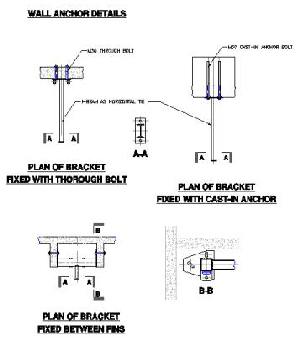

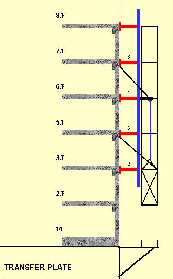

Connection to Permanent Structure |

|

|

|

|

(refer to

figure) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

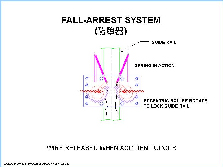

Mechanism of Fall-arrest System |

|

|

|

|

(refer

to figure) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

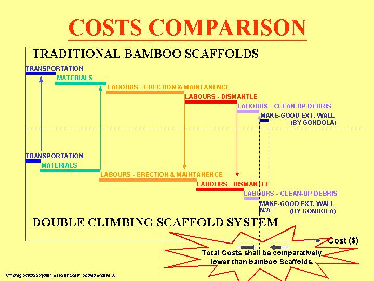

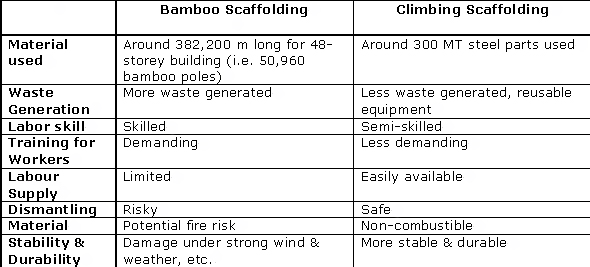

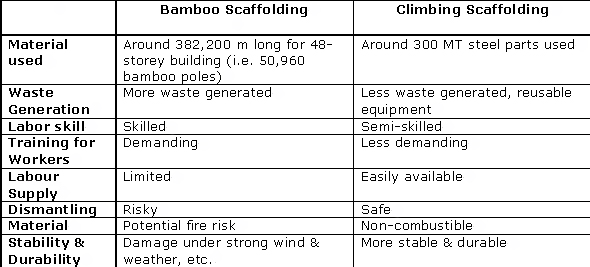

Comparison Between Bamboo and Climbing

Scaffolding |

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

Examples of Application in Hong Kong |

|

| |

Proposed

Senior Citizen Residence Area 44, TKOTL 68, Tseung Kwan O. Proposed

Senior Citizen Residence Area 44, TKOTL 68, Tseung Kwan O. |

|

|

Ocean

Shores Phase 3, Tower 16 & 17 at TKOTL 55, Tseung Kwan O. Ocean

Shores Phase 3, Tower 16 & 17 at TKOTL 55, Tseung Kwan O. |

|

| |

|

|

|

Sources |

|

| |

Tak

Hing Construction Tak

Hing Construction |

|

| |

Web site :

http://www.takhing.com |

|

|

|

|

|

|

|

|

Metal-Bamboo Matrix System Scaffold

(MBMSS)

|

|

|

|

|

|

|

|

|

|

|

In Hong Kong,

bamboo scaffolding has been the mainstream in the past. However, due

to the poor and inconsistent quality of bamboo itself, reports of

bamboo scaffolding related accidents are increasing. A vendor,

therefore, has designed a new scaffolding system – the

‘Metal-Bamboo Matrix system Scaffold’ (MBMSS). |

|

|

|

|

|

|

|

The principal

of MBMSS is to combine the good characteristics of metal scaffolding

and bamboo scaffolding. It comprises steel pipes (60%) and bamboo

poles (40%). The steel pipes are used as main poles and ledgers for

supporting the loading, and provides more stable, secure and

reliable scaffolding than pure bamboo scaffolding. The bamboo poles

in MBMSS reduce the total weight of scaffolding and increase its

flexibility. MBMSS enables flexibility and adaptability to the

various miscellaneous and different requirements which occur in

practice, providing a higher productivity and efficiency than metal

system scaffolding. |

|

|

|

|

|

|

|

Metal-Bamboo

Matrix System Scaffold is composed of two layers as

for traditional metal or bamboo scaffolding. For the outer layer,

metal tubes are used as the main posts and main ledgers while bamboo

is used as guardrail and fencing. For the other members, bamboo is

used to minimize the loading.

|

|

|

|

|

|

|

|

|

|

Typical diagram of

a standard Metal-Bamboo Matrix System Scaffold

|

|

|

|

|

|

|

Together with

other components, such as catwalks, toeboards and staircases, MBMSS

provides a stable and safe working environment and access for work.

The catwalks are made of aluminum while the toeboards are made of

plastic. These materials can be reused and help to save timber

waste.

|

|

|

|

|

|

|

Comparison of MBMSS

with Traditional Steel Scaffolding and Bamboo Scaffolding

|

|

|

|

|

|

MBMSS is about 15%

more expensive than traditional bamboo

scaffolding. The following table compares MBMSS with

traditional steel scaffolding and traditional bamboo scaffolding.

|

|

|

|

|

|

| |

Traditional

Steel Scaffolding |

MBMSS |

Traditional

Bamboo Scaffolding |

| Catwalk |

yes |

yes |

no |

| Toeboard |

yes |

yes |

no |

| Stair

access |

yes |

yes |

no |

| High

reliability |

yes |

yes |

no |

| Flexibility |

no |

yes |

yes |

| Light

weight |

no |

yes |

yes |

| High

productivity |

no |

yes |

yes |

| Minimum

of costs |

no |

yes |

yes |

|

|

|

|

|

|

|

Example

Application |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

![]() Proposed

Senior Citizen Residence Area 44, TKOTL 68, Tseung Kwan O.

Proposed

Senior Citizen Residence Area 44, TKOTL 68, Tseung Kwan O.