Miscellaneous

|

Using factory made steel fabric as reinforcement for slabs and walls, steel hoardings for longer life span, hanging cradles as working platform for exterior wall finishing work, and steel scaffolding for higher durability would all also reduce waste generation. |

Steel hoarding

|

In addition to prefabricated joinery in kitchens, prefabricated bay windows, and proprietary doorsets are initiatives of the Housing Authority intended to reduce construction waste and other costs. |

|

|

|

|

|

Precast bay window |

Prefabricated doorset |

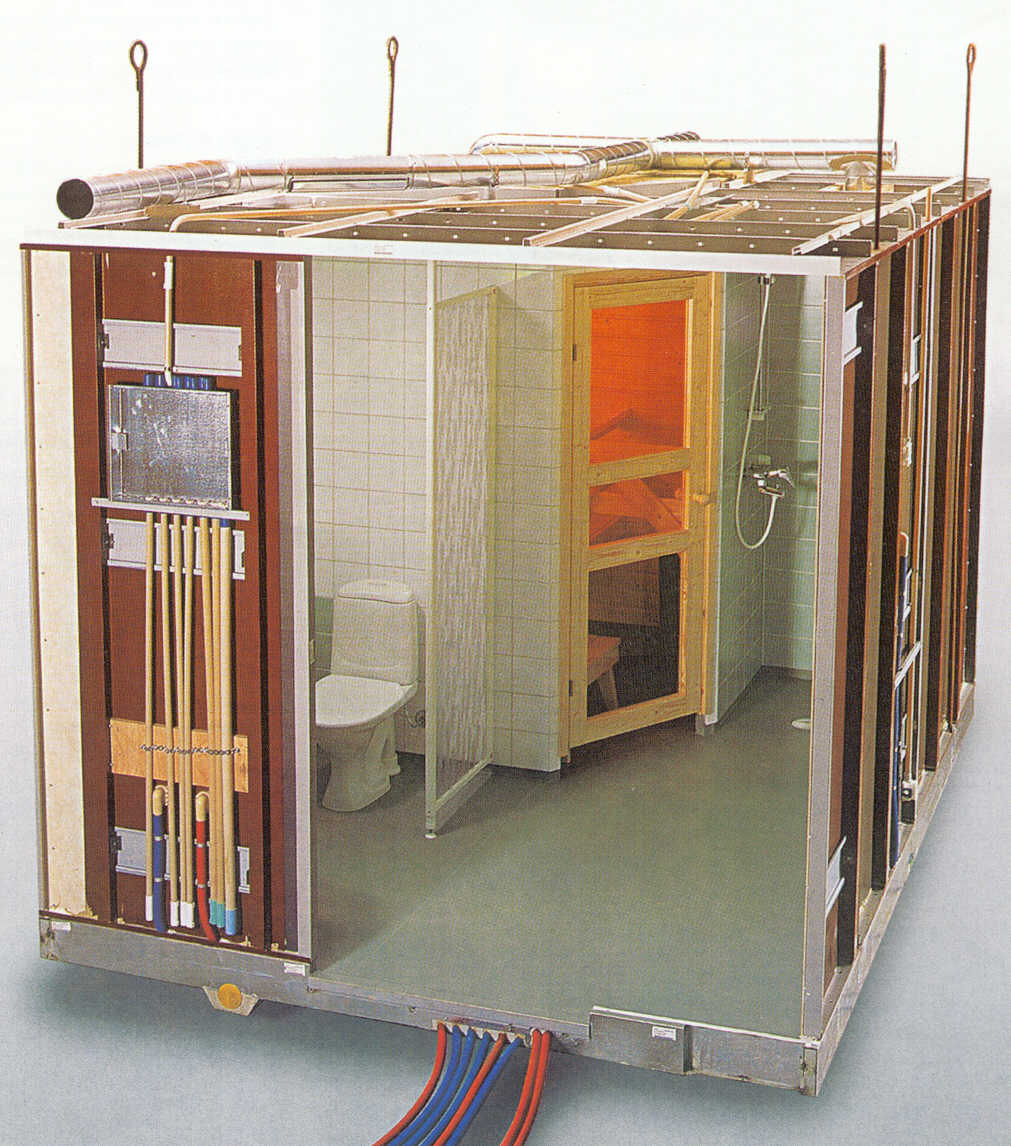

Prefabricated Unit Bathrooms are designed to provide a superior alternative to the conventional in-situ construction of bathrooms.

The walls and ceilings of the Unit Bathrooms consist of plastic-coated hot-dipped galvanised steel sheet cassettes joined together with mechanical connections. Walls are 50 mm thick and tiles are marbles are applied to the walls with a special adhesive.

The floors of Unit Bathrooms consist of a 100 mm reinforced concrete slab. To guarantee the proper flow of water to drains, the floor is pitched at the factory and a water proofing membrane is applied on to the concrete slab.

A patented PVC sanitary piping and shallow floor trap system is concealed within the floor slab structure. No sanitary pipes need to penetrate the floor slab, thus cutting down the possibility of leakages in to the apartment below.

All other M&E services are concealed within the walls and above the ceiling of the Unit Bathroom. The M&E services are tested at the factory before delivery to the site. Connections of M&E services at the site are all done from outside the unit. These locations are agreed together with the contractor before the manufacturing of the units.

Each prefabricated Unit Bathroom is subjected to thorough and stringent quality control and tests in the factory, which includes water-proofing, plumbing and electrical wiring.

| Eastern

Gotech (HK) Ltd. Unit B, 23/F, Yardley Commercial Building, No. 3 Connaught Road west, Hong Kong Tel: (852) 2866 9199 Fax: (852) 2865 0321 |

| Tseung

Kwan O Area 73A Phase-II, Hong Kong |

| Cheung Sha Wan West Phase-II, Hong Kong |

|

| Sau

Mau Ping Estate Redevelopment Phase-V, Hong Kong |

|

| Shek Yam Estate Phase-III, Hong Kong |

| Cheung Sha Wan West Phase-II, Hong Kong |

|

| Proposed

Redevelopment Oxford House at Quarry Bay, Hong Kong |

|

| Sau

Mau Ping Estate Redevelopment Phase-V, Hong Kong |

|

| Shek Yam Estate Phase-III, Hong Kong |